By seamlessly integrating advanced underground cabling technology with meticulous planning and execution, Nexans significantly contributed to the preservation and enhancement of the natural landscape in the Dorset AONB, while ensuring reliable power transmission for the region.

Context

In 2035, in Europe, combustion-powered vehicles will be banned, emphasizing the urgency of EVCI deployment. At the forefront of innovation, Nexans’ R&D center, AmpaCity, recognizes the pivotal role of Electric Vehicle Charging Infrastructure (EVCI) in advancing sustainable transportation. With a surge in electric vehicle (EV) adoption forecasted and stringent emissions regulations on the horizon, AmpaCity aims to lead by example. The installation of an EVCI at the Nexans R&D center not only facilitates employee access to EV charging but also serves as a model for future deployments.

Challenges

The implementation of EVCI at AmpaCity faced unique challenges, including the need for consensus among stakeholders, integration with existing infrastructure, and ensuring scalability for future expansion. Additionally, maintaining operational efficiency and minimizing disruptions during installation were critical considerations.

6

charging stations

30%

less time to install cables compared to classic installation

Nexans implication

Nexans leveraged its expertise in decentralized BUS & branch architecture to design and implement an efficient EVCI system at AmpaCity. Key aspects of Nexans’ involvement in the project include:

- Utilization of Nexans Cca – FR-N1X1G1-AR 0.6/1kV IRVE cables, Michaud connectors and Unex cable trays for robust and reliable charging infrastructure.

- Cables are Euroclass Cca ensuring visibility in case of fire allowing for safe evacuation (5 to 10 times less opaque smoke vs. R2V).

- Implementation of a BUS distribution system to optimize space utilization and accommodate future growth.

- Collaboration with internal and external partners to ensure seamless integration with existing infrastructure and operational continuity.

- Emphasis on time-saving installation methods, minimizing disruptions to daily operations at the R&D center.

By addressing challenges, providing innovative solutions, and actively participating in EVCI projects, Nexans plays a crucial role in accelerating the transition to sustainable transportation infrastructure.

The installation is quicker than an NF C15-100 star installation, and there are far fewer cable runs. It’s easy to fit into existing boreholes. All you have to do is install the new connections and protection to the new charging points. If there’s maintenance to be carried out, there’s no need to shut down the whole installation (…) no need to look everywhere for the main board key.

Installer Project Manager, Nexans

Context

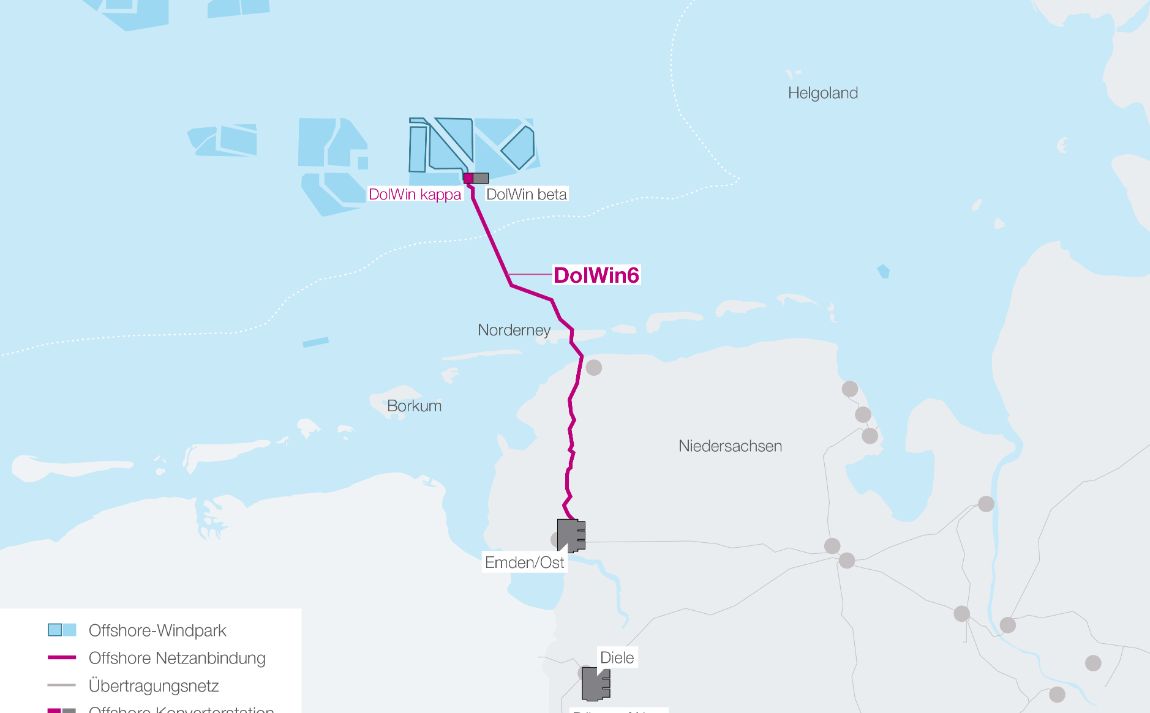

In July 2017, transmission system operator TenneT awarded Nexans the contract to supply and install the cables for the DolWin6 direct-current link. This project aims to transport electricity from the offshore wind farms of North Sea Cluster 3 from the DolWin Kappa HVDC converter station to the Emden/Ost onshore HVDC converter and transformer station. The project involved the installation of two parallel, XLPE-insulated 320 kV DC cables, each measuring 90 km in length, with a maximum output capacity of 900 MW. The project, valued at around 100 million euros, was completed in 2023 and represents one of Nexans Deutschland’s largest projects.

Challenges

The geographical location of the offshore wind farm presented challenges, as the cables must pass through the ecologically sensitive Wadden Sea. Additionally, the cables cross the island of Norderney, necessitating careful installation techniques to protect the environment and wildlife.

Key figures

900MW

Maximum output generated by wind turbines

2x320kV

Maximum voltage of the cables

2x90km

Length of offshore cables

Nexans implication

Nexans was responsible for all stages of the project related to the cable system, including design, manufacture, logistics, and installation. The Group supplied submarine XLPE-insulated 320 kV DC cables, manufactured in Norway, accessories, and installation services. Additionally, Nexans installed a fiber-optic cable for data transfer.

Land cables, produced in Belgium, were installed between Hilgenriedersiel and Emden at a distance of roughly 45 kilometers.

Low-loss high-voltage and ultra-high-voltage cables from Nexans enable grid operators to expand their grids in a way that achieves the best possible results in terms of efficiency and conservation of resources, and thereby to lay the groundwork for the energy supply of the future.

I am delighted that TenneT has awarded us the contract for this important link. With DolWin6, we are responsible for all stages of the project relating to the cable system, including design, manufacture, logistics and installation, and after previous projects such as Beatrice, Italy-Montenegro and NordLink, we once again have the chance to demonstrate our expertise in high-voltage direct-current transmission.

Managing Director, Nexans Deutschland

Context

In 2020, Nexans has been awarded a significant contract to design, manufacture, and install a 335km subsea high voltage direct current (HVDC) cable system for Ariadne Interconnection S.P.S.A, a subsidiary of IPTO, Greece’s state grid operator. The Crete-Attica interconnection aims to link the electricity network on mainland Greece to Crete, facilitating the transition from fossil fuel generation to renewable wind and solar energy resources. Crete, with a population of around 700,000 people and attracting over 4 million visitors annually, currently relies predominantly on outdated fossil fuel generation. The submarine cable interconnection promises a reliable power supply crucial for Crete’s future prosperity, while also reducing emissions and making the island more attractive to tourists. Additionally, it enables the development of Crete’s own renewable energy resources by facilitating the export of excess generation to the mainland.

Challenges

One of the primary challenges of this project lies in the complexity of installing a subsea HVDC cable spanning 335 km, from the Attica region on the Greek mainland to the Herakleion area in Crete, especially considering water depths reaching up to 1,200 meters. Additionally, the need to ensure the cable’s resilience against environmental factors and potential damages during installation poses a significant challenge. Furthermore, coordinating the manufacturing, transportation, and installation processes within the designated timeframe presents logistical hurdles.

335 km

of subsea HVDC cables

1,200 m

water depth

Nexans implication

Over a 35-month project, the Group played a crucial role throughout the project lifecycle. We provided one 500 megawatt (MW) HVDC subsea cable system to form half of the total 1,000 MW bipolar interconnection.

The Nexans cable, rated at 500,000 Volt, is based on its well-proven mass impregnated nondraining (MIND) design for HVDC cable systems and will integrate fiber optic elements for sensor applications. The near-shore sections of the cable, installed at water depths down to 100 meters, feature an aluminum conductor core with a cross-section of 1,800 mm². The deeper sections of the cable, installed at depths down to 1,200 meters, feature a 1,500 mm² cross-section aluminum conductor. The HVDC cable was manufactured in the Nexans plant in Halden, Norway.

In terms of installation, Nexans deployed one of its dedicated cable vessels, Nexans Aurora, to lay the cable along the designated route. To project the cable and ensure its secure positioning down to 600 meters water depth, we deployed the Nexans Capjet water jetting system, specialized trenching equipment.

Context

The German energy transition plan, known as “Energiewende”, has set a target for 80% of the country’s annual electricity needs to be met by renewable energy by 2050. This necessitated upgrades to the high voltage (HV) power transmission networks, particularly to transport electricity generated by wind farms in the north to consumption hubs in the south. In 2019, Amprion, a key transmission service operator (TSO), undertook the task of upgrading its transmission grid, stretching over 11,000 km, to serve more than 29 million people across a vast region. While most of its transmission lines are overhead, Amprion identified environmentally sensitive sections where undergrounding was essential to minimize impact.

Challenges

The primary challenge for Amprion was to upgrade its 400 kV transmission network to meet the demands of the Energiewende, particularly in environmentally sensitive areas where undergrounding was necessary to mitigate visual and ecological impacts. This required finding suitable technologies and partners capable of facilitating the transition while maintaining reliability and efficiency.

31.8 km

length of 400 kV Nexans cable

11,000 km

length of Amprion’s transmission grid

29 M

of people supplied

Nexans implication

Nexans emerged as a crucial partner for Amprion’s undergrounding efforts, providing innovative cable solutions tailored to the project’s needs. Initially involved in a pilot project at Raesfield, Nexans expanded its involvement by supplying 31.8 km of 400 kV cable for a major project at Legden, along the route between Wesel and Meppen. This Legden project comprised 2.1 km of tunnel and 3.1 km of pipes. Nexans supplied the cable for a double circuit with a 2,500 mm² copper cross-section, featuring halogen-free flame-retardant sheathing for safety. Additionally, Nexans provided steel support structures critical for cable installation.

Delivery of the cables, scheduled for July 2022, marked a significant milestone in the project timeline, with installation completed in 2023. The involvement of Nexans not only ensured the technical feasibility of the undergrounding endeavor but also validated the concept of partial undergrounding, offering TSOs like Amprion a flexible and sustainable approach to network upgrades.

This major contract for Amprion is a very important reference for the partial undergrounding concept that Nexans has pioneered, TSO’s no longer have to make an either-or choice between overhead lines or underground cables. Instead they can specify the most appropriate technology to meet their environmental and financial objectives appropriate for each section of their transmission routes.

Sales Manager Subsea & Land System, Nexans

Context

In 2022, Nexans has embarked on a significant endeavor to contribute to Italy’s energy transition. In collaboration with ERG, a leading company in the wind power sector in Italy, Nexans secured a contract to support the repowering of four onshore wind farms in Sicily. These farms should produce 330 GWh per year, representing consumption of 100,000 houses and 166,000 tons of CO2 emissions avoided each year. The project aims to enhance energy production capacity, reduce carbon emissions, and advance the adoption of renewable energy sources within Italy’s energy landscape.

Challenges

The project faced several challenges, including the need for advanced cable technologies, efficient delivery timelines (between May and October 2022), and the integration of digital solutions for enhanced project management. Additionally, ensuring environmental sustainability and optimizing the total cost of ownership were crucial considerations for the success of the project.

143 MW

total capacity of the 4 wind farms

330 GWh

projected annual energy production

100K

households’ equivalent energy consumption

Nexans implication

Nexans played a pivotal role in the project by offering a comprehensive solution that included cables, accessories, engineering services, and the innovative ULTRACKER digital solution. The company provided more than 400 kilometers of directly buried shockproof MV cables along with 33kV accessories, thereby improving the project’s total cost of ownership (TCO) and reducing environmental impact. Additionally, Nexans provided engineering services to optimize the collector design and grid connection for the wind farms.

The cables were manufactured at Nexans’ Battipaglia plant in the south of Italy, while the accessories were manufactured at Nexans’ Offida plant located on the East coast of Italy.

Nexans’ ULTRACKER digital solution marked a significant advancement in project management, allowing real-time visualization of cable deliveries, drum locations on-site, and monitoring of installation progress. This implementation of digital solutions in the Italian context showcased Nexans’ commitment to innovation and technological leadership in the energy sector.

Nexans’ advanced cable solutions, accessories and services provide our customers with transparent and smooth cable installation. Not only does this help put customers’ minds at ease, it’s also another example of our cutting-edge technology and ongoing commitment to R&D. ERG is a leading business in the Italian wind power sector and our ongoing partnership with them is just another step in Nexans’ journey to contribute to the energy transition and sustainable electrification in Italy.

CEO & Sales Director, Nexans Italia

Through its collaboration with ERG in the repowering of wind farms in Sicily, Nexans solidifies its position as a key player in Italy’s energy transition. The project not only enhances renewable energy capacity but also demonstrates the efficacy of advanced cable technologies and digital solutions in facilitating sustainable electrification.

Context

In April 2019, Nexans was awarded a significant contract worth 35 million euros by Morgan Sindall Infrastructure to supply high voltage underground cables for the Dorset Visual Impact Provision (VIP) project. This project, part of National Grid’s initiative, aimed to reduce the visual impact of an existing 8.8 km section of 400 kilovolt (kV) overhead line in the Dorset Area of Outstanding Natural Beauty (AONB). The primary objective was to replace the overhead lines with Nexans’ underground high voltage cables, thereby enabling the removal of 22 pylons. This transformation aimed to restore the natural beauty of the English countryside, particularly near the villages of Martinstown and Winterbourne Abbas.

Challenges

The project faced several challenges, including the need to preserve the environmental heritage and wildlife of the Dorset landscape while ensuring reliable power transmission. Additionally, the underground cabling required intricate planning and construction to seamlessly integrate with the existing infrastructure and to maintain the efficiency and safety of the power network.

+100 km

of specialized copper-core high voltage XLPE cables supplied by Nexans

22

pylons to be removed

Nexans implication

Nexans played a pivotal role in the Dorset VIP project, supplying 100 km of specialized copper-core HV XLPE cables suitable for burying underground. The cables will be used to create two, three-phase circuits, each with two cables per phase. Additionally, Nexans supplied accessories and jointing services, ensuring a comprehensive solution for the project’s needs. The manufacturing of cables took place at Nexans’ Benelux plant in Charleroi, Belgium, while accessories were delivered from Nexans’ Switzerland plant in Cortaillod. The jointing services were provided by Nexans’ UK installation team, securing the seamless integration of the underground cables.

Construction work on the project started in spring 2019 and took three years to complete, including the removal of the existing line and pylons.

We are delighted to be involved in this key National Grid project to demonstrate the capability of our underground cables to mitigate the visual impact of HV power links. Nexans has been deeply involved with Morgan Sindall Infrastructure from the start of the project design process and we have already reached the stage where the cable system is being further refined and optimized.

Business Development Director UK/Ireland Subsea and Land Systems, Nexans

Context

Operational since 2021, the Resilient Electric Grid (REG) project in Chicago aims to bolster the city’s electrical grid against extreme weather and catastrophic events. In collaboration with American Superconductor (AMSC) and Commonwealth Edison (ComEd), the project seeks to interconnect assets in downtown Chicago using superconducting cables. These cables offer high current density, compact installation footprint, and minimal environmental impact, making them ideal for densely populated urban areas.

Challenges

The existing architecture of urban power distribution substations isolates them from each other to prevent cascading effects from fault currents. However, this limitation restricts the grid’s resiliency and recovery options during outages caused by severe weather or attacks. The project addresses the challenge of mitigating the impact on this critical infrastructure of power outages and blackouts.

12 kV

The cable operates at 12 kV.

3000 A

It carries an AC current of 3000 A.

62 MVA

It can carry up to 62 MVA of power, surpassing the capabilities of conventional resistive conductors like copper and aluminum.

Nexans implication

Nexans plays a crucial role in the REG project by designing, manufacturing, and installing the superconducting cable. Using AMSC’s proprietary Amperium high temperature (HTS) superconducting wire, Nexans produces a medium voltage cable capable of carrying high currents and power levels, which can operate at 12 kV. The cable carries an AC current of 3000 A and can carry up to 62 MVA of power, far exceeding what is possible with conventional resistive conductors such as copper and aluminum. The cable’s compact footprint and low environmental impact make it well-suited for urban deployment.

The HTS cable and the connection for the REG system were manufactured at Nexans’ specialized superconductor facility in Hanover, Germany. The power accessories were designed at Nexans’ Calais plant. AMSC is managing the project and has provided the liquid nitrogen refrigeration system, in addition to the Amperium HTS wire. The company’s collaboration with AMSC spans over 18 years, underscoring its commitment to advancing superconductor technology.

We’re excited to use this technology to strengthen critical energy infrastructure in downtown Chicago. This REG project affirms Nexans position as the world leader in HTS cable technology and demonstrates that superconducting, high-power, medium voltage cable technology is commercially viable. We have collaborated with AMSC on superconductor projects for over 18 years and are pleased to continue this long-standing and special partnership.

Corporate Vice President Innovation, Services, and Growth, Nexans

Context

Aligned with the Sustainable Development Goals, particularly SDGs 7 and 13, the Ivorian Government initiated the National Rural Electrification Programme (PRONER) in 2013. This program aimed to foster decentralized electrification and renewable energy development, including solar, biomass, and small-scale hydropower.

In the pursuit of extending electricity access to rural communities in Ivory Coast, Nexans has undertaken a transformative project as part of the country’s Program. Despite significant progress in electrification over the past decade, with nearly 70% of the population gaining access to electricity, rural areas still face a substantial deficit, with over 60% remaining unconnected. In response, PRONER targeted grid expansion to connect all settlements with over 500 inhabitants by the end of 2021 and all rural communities by 2025. Nexans’ initiative aligns with the broader national goal of enhancing rural electrification by connecting settlements lacking power infrastructure.

Challenges

The challenges of rural electrification in Ivory Coast include the lack of suitable equipment and products, infrastructure limitations, and the logistical difficulties of reaching remote areas. Additionally, ensuring the sustainability and reliability of power supply in these regions is a significant challenge.

400 km

of aerial medium-voltage (MV) cables

430 km

of low-voltage (LV) aerial-bundled cables

50

communities electrified

63

outdoor transformers installed

Nexans implication

In 2021, Nexans has successfully brought electricity to 50 rural communities across Ivory Coast, involving the installation of 400 km of aerial medium-voltage (MV) cables, over 430 km of low-voltage (LV) aerial-bundled cables, and 63 outdoor transformers.

Nexans played a pivotal role in facilitating the electrification efforts by providing a turnkey solution under its NEOGRID® system. This comprehensive solution included engineering, supply, and installation of the entire power network, encompassing cables, transformers, poles, junction boxes, and circuit-breakers. Notably, Nexans’ local plant in Abidjan played a crucial role in supplying all critical equipment, thereby supporting local manufacturing and ensuring timely delivery of components.

At Nexans we have adopted a very practical approach to supporting Africa’s transition to a more connected and sustainable energy network. In Côte d’Ivoire this is based on two inter-related pillars. First, in 2018, we opened our new Abidjan plant to help address the lack of suitable equipment and products for electrification by enabling local production based on our international and standardized expertise. Now we have taken the next step by rolling out products from the plant as part of our turnkey solution to bring electricity to rural communities.

Former Marketing & Strategy Director for Building & Territories segment, Nexans

By leveraging its expertise and local resources, Nexans is not only advancing electrification efforts but also fostering socio-economic development and improving the quality of life for thousands of Ivorians.

Context

Australia is experiencing a significant surge in solar power capacity, with projections indicating a nearly twofold increase to over 12GW. As a pivotal contributor to this growth, Nexans has been instrumental in supplying specialized power cables for six – Kiamal, Susan River, Childers, Oakey II, Nevertire and Middlemount – solar farm projects in the states of Queensland, Victoria, and New South Wales.

Challenges

The expansion of solar power infrastructure presents various challenges, including the need for high-quality, reliable power cables capable of withstanding environmental factors and meeting project specifications. Nexans navigates these challenges by providing specialized engineering support, ensuring compliance with standards and specifications, and offering innovative solutions to address unique project requirements.

672 MV

total capacity generated

+600K

homes powered

12 GW

solar capacity in Australia

Nexans implication

Nexans played a multifaceted role in the success of the solar farm projects:

- Supplying specialized power cables: Nexans supplied medium voltage (MV) and low voltage (LV) direct current (DC) cables tailored for each project’s requirements. The scope of supply included a comprehensive range of Keylios products, such as underground 33kV cables, underground 1,500V low voltage cables, photovoltaic (PV) under-array cables, underground data cables, inverter to transformer connectors, communication, tracker controls, and associated accessories.

- Providing engineering support: Nexans collaborated with solar farm EPC Contractors during the design stages of all six projects, offering specialist engineering support. This involved ensuring adherence to standards and specifications, as well as providing expertise in cable and system design.

- Manufacturing and supply: The power and control cabling were manufactured and supplied by Nexans’ facilities in China and Australia. The company’s plants in Yanggu (China) and Lilydale (Australia), supported by Nexans Olex specialist manufacturing partners, facilitated the production and delivery of high-quality cables.

- Innovation and sustainability: Nexans continues to invest in ongoing cable testing and innovation to meet the evolving requirements of Australia’s renewable energy projects. The incorporation of Nexans Olex EcoTerm™ solution in underground power cables demonstrates the company’s commitment to sustainability by providing an effective barrier against degradation from termites.

The generating capacity of the six solar farms will total 672 MW, enough electricity to power over 600,000 homes. They were commissioned between 2019 and early 2020 and we are continuing to invest in ongoing cable testing and innovation to meet the requirements of Australia’s renewable energy projects.

Context

Equinor awarded Nexans the contract to supply static and dynamic cabling and associated accessories for the world’s first floating wind farm, following a successful demo facilitated by Nexans’ cables which have been in operation since 2009 in Norway. The project aimed to harness the best wind resources by deploying floating turbines further out to sea. The Hywind Scotland Pilot Park, located 30 km off the coast of Aberdeenshire, consists of five wind turbine generators connected through an inter-array cable network, delivering energy back to land in Peterhead, Scotland.

Everything started in 2009 when Equinor’s (former Statoil) “Hywind Pilot”, the first full-scale floating wind turbine, was put into test operation 10 km off the island of Karmøy, Norway. The Hywind Demo project completed eight years of flawless operation. Nexans supplied the 15MW cable that connects the turbine to the island of Karmøy and the transformer station located there.

Challenges

The main challenge was to prove the concept of floating wind power as a viable competitor in the energy market. Despite the successful demo in Norway in 2009, many technological challenges remained to be overcome to demonstrate the cost efficiency and reliability of floating wind farms.

30 MW

floating farm capacity

13.6 km

of XLPE cable

Approximately

20K

Scottish homes powered

Nexans implication

The group played a crucial role in overcoming the challenges by providing specialized cables for both the initial pilot project in Norway and the Hywind Scotland Pilot Park. The Nexans’ specialized facility in Halden designed, manufactured and tested the 13.6 km long 24 kV XLPE-insulated submarine cable, while the Rognan factory supplied the integrated optic fiber element. Additionally, Nexans supplied static and dynamic cabling, ensuring the offshore cable system was tested, sealed off, and delivered ready for installation on site.

Since 2017, the Hywind Scotland wind farm now generates enough energy to power roughly 20,000 homes, showcasing the potential for larger floating wind farms in other areas. The success of this project underscores Nexans’ commitment to driving innovation in the offshore wind industry.

This project is a great example of Nexans pioneering alternative offshore wind design, extending the options for renewable energy generation. The contract establishes Nexans as leaders in offshore wind innovation by designing specialist cables for both the initial pilot project and the Hywind Pilot Park.

Chief Operations Officer and Senior Executive Vice-President, Nexans