- Nexans is to invest over €90 million in the development of an innovative plant at its Lens site by 2026.

- Nexans’ strategic supplier for this investment is Continuus Properzi, a specialist in continuous casting, rolling and smelting technologies for copper and aluminum.

- With a production capacity increased by over 50%, the future Lens plant will be able to recycle up to 80,000 metric tons of copper per year.

- Nexans is reaffirming its capacity to plan for any shortages of copper, a metal essential to global sustainable electrification, while also consolidating its industrial base in France.

Nexans, a global leader in electrification, has announced a major industrial partnership agreement with Continuus Properzi, a specialist in continuous casting technologies, to build an innovative copper production and recycling plant at the Nexans site in Lens, northern France, for 2026.

Global demand for copper is continuing to increase and recycling is emerging as a key solution to possible shortages of this metal, which is essential to electrification. Nexans is taking steps to address this major challenge with a project on a unique scale.

This strategic decision is based on the operational expertise of the Nexans site, founded in 1971 in the industrial center of Lens, and the technological expertise of Continuus Properzi, a supplier of complete installations for the production of ETP (Electrolytic Tough Pitch) and FRHC (Fire Refined High Conductivity) wire rod. The objective is to continuously produce wire rod from recycled copper, through a state-of-the-art refining method using up to 100% of recycled metal, while optimizing water and energy consumption.

The Lens plant is the only copper rod foundry in France. With this investment of over €90 million, it will increase its wire rod production capacity by over 50%, and boost its copper scrap recycling capacity to manage up to 80,000 metric tons per year. Nexans is already actively involved in cable recycling through Recycâbles, a joint venture set up with Suez in 2008. With this new initiative, the Group has become a key player in the circular economy of the European copper industry. Implemented for the first time in France, this process will help to create a circular model by collecting waste from different sectors of industry across France and reusing it virtuously for new finished products.

As the leading global player in this sector with its own copper foundries, Nexans is vertically integrated. The Group is entirely self-sufficient in terms of the copper supplies required for its entire cable production value chain. This key strategic advantage will be consolidated by the new plant, which will allow the Group to recycle more cables from construction sites or “urban mines”.

Nexans’ ambition is to adapt the life cycle of its products, reducing their carbon content, while also decreasing the carbon footprint of the cable industry as a whole. This investment is also part of the Group’s efforts to raise the proportion of recycled copper in its cables to 30% by 2030.

The new site further consolidates Nexans’ presence in Lens, increasing the number of jobs while creating a new working environment for staff. This project is part of France 2030, the investment plan for France. It is also in line with the company’s E3 performance model, bringing together Economic performance, the Environment and employee Engagement.

Recycling preserves biodiversity. By choosing to increase its recycling capacity, Nexans is proving that it is possible to reconcile industrial performance with the preservation of biodiversity. Through this investment in its historic Lens plant, Nexans is ensuring its strategic independence and staying ahead of the raw materials crisis, serving its customers and partners. By supporting employment and investment at our metallurgical site, we are also proving that an innovative industry can be a local industry. I am particularly proud of this partnership, which strengthens our supply chain and enables us to better anticipate a fundamental trend for the Group and our customers, where today’s waste will become tomorrow’s growth.

CEO , Nexans

I feel extremely proud to have signed this strategic agreement with Nexans, a highly prestigious name in cable manufacturing. Our collaboration is based on the recycling of copper scrap, a subject we have been working on for many years, dating back to the pioneering days when my father first developed the technology for the continuous casting of copper rod. In compliance with the exacting requirements of Nexans engineering and the Lens site in particular, we have configured an installation that will meet the highest standards in years to come in terms of industrial performance, energy savings and environmental footprint. It gives me immense satisfaction to witness the beginnings of such a fundamental project. For me, it is the crowning achievement of a personal journey that began over fifty years ago and whose purpose has always been to improve the technology used in wire rod production, this being the first step in the industrial value chain of all power cables.

President, Continuus-Properzi

All our press releases

Read all- Nexans invests 90 million euros in its facilities in Charleroi, Belgium, Erembodegem, Belgium and Calais, France to support the growth of offshore wind and subsea interconnections.

- The investment will include the construction of a new, 53 meter tower for the insulation of onshore cables at Nexans’ plant in Charleroi, Belgium, and will allow for the production of 525kV onshore cables necessary to support the TenneT frame agreement.

- Nexans is committed to a long-term strategy of electrification made possible only through the support of renewable sources of energy.

Nexans announces plans to invest 90 million euros to support the growth of offshore wind in Europe. The investment will include the construction of a new, 53 meter tower for the insulation of onshore cables at Nexans’ plant in Charleroi, Belgium and will allow for the production of 3,000 mm2 525kV HVDC onshore cables necessary to support TenneT’s three grid projects, BalWin 3, LanWin 4, and Lanwin 2 under the frame agreement signed last year.

Nexans is committed to a long-term strategy of electrification made possible only through the support of renewable sources of energy. This investment will enable Nexans to fulfill this vision and drive the next electrical revolution forward.

The investment will also include upgrades to the cable manufacturing process such as a new stranding line and a degassing system specifically designed for HVDC cables and a new aluminum drawing line to increase our volume of aluminum wire production. While the majority of the investment will be directed at upgrading its manufacturing plant in Charleroi, Nexans’ other facilities will also get a boost including a new HVDC lab with a hall specifically built for 525kV HVDC testing at its Calais facility in France, and a new injection press at its power accessories facility in collaboration with teams in Erembodegem, Belgium. The investment will begin in 2025 and run through 2026 when the work is completed.

The Charleroi plant will also connect to the La Sambre channel which will allow Nexans to reduce transportation CO2 emissions by 85%. The city of Charleroi has already begun a project to establish a multimodal transportation platform in this area.

We are pleased to announce this new investment reinforcing our position as a leader in the energy transition. The ability to produce land cables up to 525kV is a game changing capability that will enable us to drive the transition forward for years to come. We are looking forward to completing this critical upgrade in our infrastructure to keep pace with the ever-increasing electricity demand globally.

EVP of Generation and Transmission Business Group, Nexans

All our press releases

Read all- Nexans invests 15 million euros in its historical plant in Bourg-en-Bresse to increase its production of low-carbon medium-voltage cables, in order to support growth in electrification requirements in France and in Western Europe.

- The project involves installing two new latest-generation production lines and modernizing the entire manufacturing flow, and will roll out from H1 2025 to H1 2026.

- The Group is thus stepping up its capacity to manufacture EDRMAX® direct-buried cables, which are simpler to lay and reduce the system’s carbon footprint.

Nexans announces plans to invest 15 million euros in its production plant in Bourg-en-Bresse, Auvergne-Rhône-Alpes (east-central France). The investment will increase the plant’s medium-voltage cable production capacity with a view to supporting distribution grid operators and installers, and to supplying renewable energy projects, including solar and wind farms, in France and in Western Europe.

At a time when demand for electricity is booming and the challenges around it are becoming increasingly crucial, Nexans confirms its role as a prominent partner for the stakeholders in Europe’s electricity distribution systems.

The investment, which will be made from 2024 to 2026 will notably involve installing a new stranding machine that can produce new, larger aluminum cable sections, including 400 mm² ones. Nexans will also invest in a new XLPE triple extruder with the best technology in its class. All these machines will be up and running in H1 2026.

Meanwhile, the Group will modernize part of its industrial capacity, in particular the sheathing and assembly lines, to enhance employee safety and plant productivity. With these upgrades, Nexans also plans to strengthen its production of EDRMAX® reinforced direct-buried cables1, which have been proven to simplify laying processes, reduce costs and minimize carbon footprints.

The workshops will also be equipped with cutting-edge digital tools to improve controls’ quality and enhance employees’ experience. Modernizing its processes will turn the Bourg-en-Bresse plant into a 4.0 digital factory geared for sustainable, local production and make it particularly attractive to young talents.

We are very proud to announce this major investment by Nexans in its historical Bourg-en-Bresse plant. Besides maintaining our high standards of safety for our employees and of quality of service for our customers, this new ultramodern production equipment will enable us to better meet evolving demand from the big players in the energy sector. Lastly, modernizing the plant will enable us to offer them even more high-performance, low-emission cables.

Vice-President Power Distribution Cables & Accessories, Nexans

All our press releases

Read all- Nexans is investing €4.5 million in its Draveil site to double production capacity of medical cables in response to growing demand.

- The NEWSENSE® micro-cables will be produced by machines entirely designed and manufactured by Nexans.

- Building on the expertise and know-how of the Draveil workforce, the Group is developing its cable offering dedicated to minimally invasive surgical technologies, pushing the limits of miniaturization.

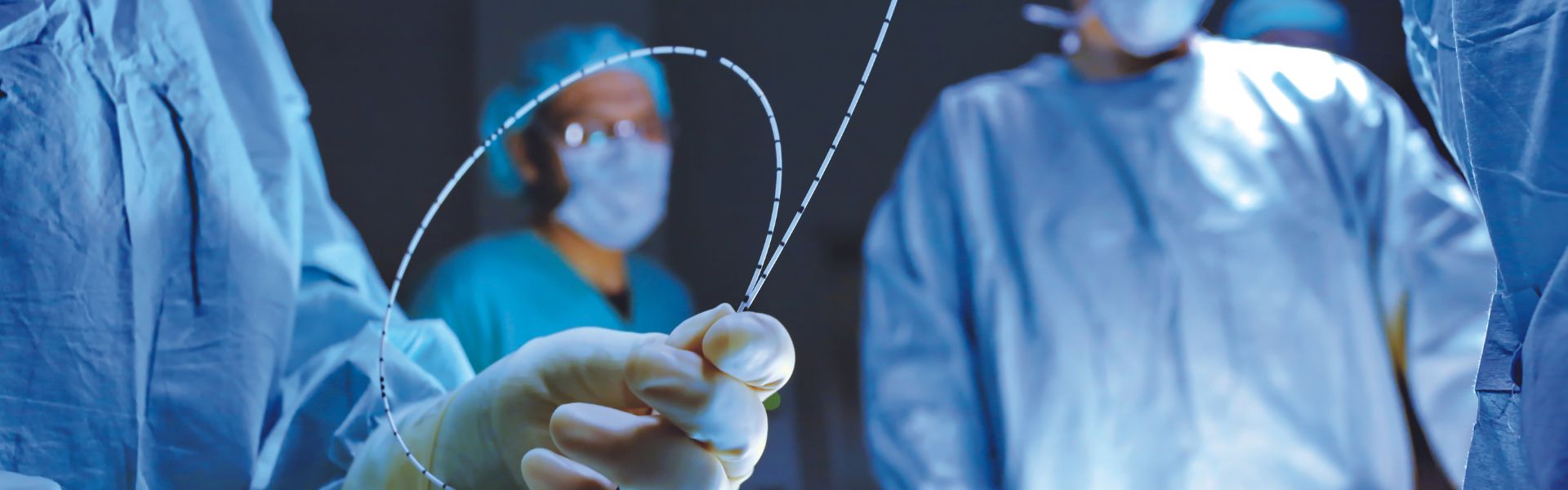

A leading designer and manufacturer of cable systems and services, Nexans has announced a €4.5 million investment in its Draveil site outside Paris to double its production capacity for medical cables.

With this investment, Nexans will be able to meet growing demand for medical micro-cables used in invasive surgery, a fast-growing market expected to achieve annual growth of 5% a year over the next five years. These cables are used in particular for transcatheter technology and cardiovascular electrophysiology, as well as for monitoring sensors and endoscopy cable solutions.

Through this investment, Nexans will be able to develop its NEWSENSE range of medical cables in a new workshop expanding the existing facilities at the Draveil site. The Group is reaffirming its commitment to manufacturing in France, particularly for products requiring a high level of expertise, as it is the case in the medical field.

These cables meet the most stringent quality standards and will be manufactured on machines specially designed and built by the engineering teams at Nexans Draveil, as they seek to continuously push back the limits of miniaturization. As these machines do not yet exist on the market, they wil further sharpen the competitive edge of Nexans, allowing it to consolidate its position as an industrial leader in cutting-edge technologies.

Consolidating our medical business is one of the strategic development goals set for our Aerospace & Medical division. Our high-performance cables are particularly well suited to environments demanding compliance with standards ISO 13485 (medical) and EN 9100 (aerospace) for safety and reliability. These particularly demanding standards are recognised by our customers worldwide.

Vice President Aerospace & Medical, Nexans

Delivering the speed and efficiency necessary to stay competitive in this niche market, these machines also meet the highest standards of reliability and quality, with the use of optical control technology to inspect the cables on the production line.

With this investment, Nexans will be able to develop its offering for medical OEMs, a field in which the company has over 30 years’ experience. With a dedicated plant and laboratory, Nexans is setting the standard in the supply of micro-cables for devices used in medical exploration as well as in diagnosis and treatment, greatly improving comfort for both healthcare professionals and patients alike.

With this investment, we are strengthening our position in the medical cable market and taking production capacity to a new level, with our machines and technology we push the limits of miniaturization. We are particularly pleased to be making this investment in Draveil, allowing us to expand with a new workshop dedicated to this market segment.

Executive Vice President Industrial Solutions & Projects, Nexans

- Nexans has officially opened the newly expanded section of its high voltage subsea cable plant in Halden, Norway to support the increased demand globally for electrification and the energy transition.

- Nexans’ investment created more than 100 jobs and will be able to deliver 525kV HVDC and 420kV HVAC subsea cables.

- The plant incorporates the most advanced cable production technology to date and features a second extrusion tower which will allow the plant to insulate four cables simultaneously in two existing lines, in addition to the two existing lines in the old tower. The new tower will be the tallest building in Norway and the country’s first skyscraper.

- The Halden plant also celebrates its 50th anniversary, marking a key milestone in Nexans’ 109 year history in Norway.

Nexans, a leader in the world’s transition to a more connected and sustainable future has officially opened its newly expanded section of its high voltage subsea cable plant in Halden, Norway to support the increased demand globally for electrification and the energy transition. The expansion project will support key projects including Nexans’ frame agreement with TenneT signed last year.

The construction for the expansion of the plant began in November 2021 and incorporates some of the most advanced cable production technology which will be able to deliver subsea cables up to 525kV for High Voltage Direct Current (HVDC) and 420kV for High Voltage Alternating Current (HVAC). The 34,000 square meter expansion more than doubles the capacity of the plant for HVDC extruded cables. It also features a 152.89 meter tall second extrusion tower which will allow the plant to insulate four cables simultaneously in two lines, in addition to the two existing lines, and qualifies as Norway’s tallest building and first skyscraper. The tower will be focused on the production of HVDC cables for offshore wind farms, but can serve both HVDC and HVAC applications. 100 more people have been hired and trained to support the increase in production from the facility and local indirect jobs will also be created to support the supply chain in Europe and globally. This brings the total employment of the plant up to around 1,000 employees on site.

The Halden plant also celebrates its 50th anniversary. Having been originally built in 1974 to support the Skagerrak 1 and 2 interconnector projects in cooperation with Statnett, the facility has been involved in projects across the globe. The first extrusion tower was built in 1992 to incorporate the first high voltage XLPE insulated cables into Nexans’ portfolio. The plant also features a state-of-the-art testing facility for high voltage components as well as its own slip to load cables directly onto cable laying vessels such as Nexans’ CLV Aurora, C/S Skagerrak, and Nexans’ newest vessel under construction, the CLV Electra.

Our investment in Halden significantly increases our production capacity and illustrates Nexans’ commitment to sustainability and the global energy transition. The plant will supply international markets with cables for key offshore wind farms and interconnectors that will bring renewable energy from the areas of high supply to those of high demand.

CEO, Nexans

The importance of the newly expanded Halden plant cannot be overstated. In a world that is rapidly becoming more electrified, the expansion of cable production will supply a critical need in Europe and globally. We are excited to work with our customers on producing the most technologically advanced cables to date, which will connect renewables to shore and electricity across continents.

EVP of Generation and Transmission Business Group, Nexans

All our press releases

Read all- Two agreements have been signed with Morocco’s Ministry of Industry and Trade, Ministry of Energy Transition and Sustainable Development, Ministry of Investment, Convergence and Evaluation of Public Policies, National Office of Electricity and Drinking Water (ONEE), and Moroccan Investment and Export Development Agency (AMDIE) to build a new medium-voltage cable plant in the country involving a total investment of €100 million, by 2026.

- With the goal of supporting the energy transition in Morocco and Africa, the project is expected to create more than 200 direct jobs.

Nexans and the Moroccan Ministry of Industry and Trade, Ministry of Energy Transition and Sustainable Development, Ministry of Investment, Convergence and Evaluation of Public Policies, the National Office of Electricity and Drinking Water (ONEE) and the Moroccan Investment and Export Development Agency (AMDIE), signed two agreements involving a €100 million as a total investment plan to build the company’s third plant for medium-voltage cable in Morocco by 2026, in addition to its facilities in Casablanca and Mohammedia.

Strengthening Nexans’ commitment to the energy transition in Morocco and across Africa, the project is expected to create more than 200 direct jobs and will benefit from the backing of the Moroccan Ministries, the ONEE and the AMDIE. Moreover, it will meet the Group’s standards of excellence, in line with its Industry 4.0 digitalization and sustainability goals, and will deliver cables to Africa.

This project is aligned with the High Instructions of His Majesty, King Mohammed VI. Currently a leader in the region and across Africa in the deployment of renewable energy infrastructure, Morocco aims to consolidate the entire industrial ecosystem in the years to come. Through this transformative project, Morocco and Nexans are working together to strengthen the development of the renewable energy industry value chain in the Kingdom and to promote technical advancement in the local industrial fabric.

Once again, I commend Morocco’s outstanding leadership in bringing the benefits of sustainable electrification to all. I am delighted with this new phase in our relations, which boosts our presence in the country, where we have been operating for more than 75 years, alongside our plants in Mohammedia and Casablanca. This project, bringing together public and private players, sets out to achieve, from the very start, ecological and human commitments, thereby unlocking significant economic potential for all of Africa.

CEO, Nexans

This project is central to the key directives of the roadmap issued on High Instructions of His Majesty King Mohammed VI, may God assist Him, which were reiterated last March. I would like to express my praise for the support of the Ministries, which made this agreement possible. We are proud to strengthen our presence in Morocco.

Managing Director, Nexans North & West Africa

Press releases

Read all- Nexans is investing in a new cutting-edge cable laying vessel to support a record project backlog and meet future needs in a booming offshore wind and interconnection market.

- This unique and pioneering vessel builds on the capabilities of the Nexans Aurora, with an enhanced loading capacity and the ability to lay four cables simultaneously.

- This vessel will be delivered in 2026.

Nexans, a world leader in the cable system design, manufacturing and services, has announced an expansion in its presence in the offshore wind and interconnection market, by adding a third cable laying vessel to its fleet.

This strategic decision will allow the Group to meet the increasing demand for electrification, especially in the American and European markets, driven by a record project backlog and recently strengthened by the historic €1.7 billion contract with TenneT, and €1.43 billion contract for Great Sea Interconnector project.

This new strategic asset will also directly and indirectly create hundreds of jobs worldwide during its construction and operational period.

A new ship with unprecedented capabilities

Building upon the cutting-edge technology featured on Nexans’ flagship vessel, the Nexans Aurora, this new ship goes further with improved design, comfort and capabilities. Equipped with three turntables, offering a 13,500-tonne loading capacity, and hosting a large range of subsea tooling including jetting and ploughing tools, this vessel will be capable of laying up to four cables simultaneously to meet specific customer requirements, especially on large-scale projects.

By adding this vessel to its fleet, Nexans is also enhancing its versatility and flexibility covering a widening geographical footprint.

From an environmental standpoint, the new vessel with its increased load capacity, an advanced hybrid power system and capable of running on biodiesel mix, will offer a significant reduced footprint, reflecting the Group’s strategic environmental vision.

This new vessel will be the most technologically advanced cable layer ever deployed. Fitted with a range of high-tech cable installation and burial equipment, it will enhance the capabilities of our subsea cable operations to tackle projects on an unprecedented scale. This new strategic asset will support the Group’s long-term growth, consolidating its leadership in the interconnection and offshore markets. It perfectly embodies Nexans’ strategy to electrify the future, and its innovative features illustrate our ever-increasing commitment to meeting our partners’ needs.

Chief Operations Officer and Senior EVP, Nexans

Press releases

Read all our press releasesNexans announced a 40 million euros investment in its Autun site, the epicentre of a more global strategy of innovation, sustainable development and social commitment.

Present in Autun since 1979, Nexans announced today, in the presence of Jean Mouton, Chairman of Nexans Group, Christopher Guérin, CEO of Nexans and Guillaume Teixeira, Managing Director of Nexans France, the investment of 40 million euros over the next three years in its Autun site, in order to perpetuate the site’s know-how, its industrial competitiveness and employment in France.

This announcement comes at a key moment in the Group’s strategy, reaffirming its commitment to the electrification of the future in France, the cradle of the company for 120 years. Through this investment, Nexans will:

- Accelerate the automation and digitisation of the Autun plant to make it a showcase for the Group’s transformation towards Industry 4.0;

- Reinforce its commitment to circular principles in the use of recycled materials, in particular in connection with its Lens site, the only copper casting facility in France;

- Anticipate changes in fire safety standards for commercial buildings, expected in 2023, by making its Autun plant a European benchmark in fire safety technology.

With demand for electricity expected to increase by 40% by 2040 and limited raw material reserves, Nexans is capitalising on its French territorial roots to build a strong and sustainable ecosystem around three key pillars: innovation, circularity and the use of new industrial technologies. These three pillars are illustrated today in Autun by this major investment of 40 million euros. The aim is to support the production capacity and competitiveness of the site, which is at the forefront of the industry’s new fire safety challenges, and to contribute to its ambition of carbon neutrality.

In concrete terms, the Autun plant will:

- Become a European reference in fire safety technology. This is a major challenge at a time when France, which is exemplary in terms of electrification, is considered to be lagging behind other European markets in terms of fire safety issues in buildings. Nexans is already anticipating the changes in fire safety standards planned for tertiary buildings (ERP) in 2023: from 2025, 30% of electrical installations in buildings will have to include cables that limit the emission of toxic fumes in the event of a fire. Nexans is capitalising on this expected change in standards to make the Autun site a European centre of expertise in PVC and halogen-free compounds;

- Strengthen its ability to supply cables made from recycled materials, in particular by improving the circularity of copper, a primary resource that is becoming increasingly scarce. The vertical integration of Nexans’ value chain in France, from its metallurgical site in Lens, is a decisive asset. It allows Nexans to secure supplies, guarantee the continuity of its activity, and support its customers in reducing their carbon footprint. Through this investment programme, the Autun site also aims to reduce the carbon footprint of its production process by more than 4.2% per year, in particular by modernising its equipment, deploying energy saving solutions and reducing the consumption of fossil fuels on the site.

- To make its Autun site the test-site for an ambitious Industry 4.0 programme, which is intended to be extended to all Nexans sites worldwide from 2023. In addition to the benefits in terms of industrial productivity, Nexans is aiming for a massive improvement in the safety of its teams and industrial processes, in connection with the training of its employees in the field of automation. Industry 4.0 use cases will be developed there, for greater flexibility and agility: performance monitoring, energy consumption monitoring and real-time data to digitise production indicators and routines.

The site, which employs 200 people in the region, is part of Nexans’ network of 14 plants in France, which employs 2,300 people. Since 1979, the Group has invested between 2 and 3 million euros per year in this plant, which also became the first 100% automated logistics platform in France in 1996. A showcase for the Group’s innovation, several building electrification solutions developed in Autun have since been replicated in other markets and have become essential in France. For example, these solutions facilitate the daily work of 30,000 electricians thanks to cables that are easy to unwind, locate and strip: Distingo NX’TAG, Passeo, Easyfil, Mobiway.

Nexans is a company with strong local roots in France. We believe in a modern, innovative and environmentally sustainable industry. Our vertical integration in the country safeguards supply for our customers and their ability to reduce their carbon footprint. This is why Nexans is investing and will continue to invest to maintain industrial jobs in France.

President, Nexans Group

France is a country at the forefront of the challenges of electrification, with national champions that have become world leaders in the entire value chain. I am deeply convinced that our country must turn a new page in its industrial history, in order to ensure French sovereignty in electrification. At our level, we are doing this every day here in Autun, and more widely in France, by relying on our unique vertical integration model, from our metallurgy unit in Lens, our AmpaCity global innovation centre inaugurated in Lyon in 2022 and our other production sites in France. All our teams are very proud of this investment, which supports our ambition to electrify the future.

Managing Director, Nexans France

Find all our press releases

Read allOn Wednesday December 7, 2022, Ryad Mezzour, Moroccan Minister of Industry and Trade, and Christopher Guérin, CEO of Nexans Group, inaugurated the Nexans photovoltaic power facility in a ceremony held on the group’s site in Mohammedia, in Morocco.

The facility is installed on the roof of the Mohammedia plant, comprising 4,640 photovoltaic panels – for an installed capacity of 2.5 MWp – that cover a total surface area of 12,166 square metres. It will produce more than 3,927 MWh of electricity annually, a capacity that will guarantee a substantial reduction of more than 2,850 tonnes per year in CO2 emissions, and cover 19% of the plant’s energy needs.

The choice of Nexans Group is in line with Morocco’s objectives to develop a clean, decarbonised and environmentally responsible industry.

Minister of Industry and Trade, Morocco

“Under the leadership of His Majesty King Mohammed VI, may God assist him, our country has been a pioneer in the development and use of renewable energies which today present an alternative. It is thanks to this alternative that manufacturers can both reinforce their competitiveness, reduce their energy bill and contribute to mitigating the impact of climate change,” said Mr. Mezzour. He went on to specify that “the energy transition is now an industrial imperative that must be approached as an opportunity to be seized.”

For Christopher Guérin, this inauguration lies at the heart of Nexans’ agenda, which has made the climate emergency a priority, with a firm commitment to reduce its greenhouse gas emissions by 4.2% per year by 2030.

The Mohammedia facility is central to one of our Group’s best performing business units. This success attests to 75 years of strong ties between Nexans and Morocco, and paves the way for a common roadmap in terms of sustainable electrification, in particular through ambitious investment projects.

CEO, Nexans

For her part, Selma Alami, Nexans Managing Director for North and West Africa, stressed the importance of the inauguration’s context. “Morocco is moving up a gear in the development of renewable energies in order to guarantee its energy security while positioning itself as one of the most attractive global destinations in terms of green industrialisation.”

Thanks to its historical legitimacy, and driven by the Kingdom’s industrial ambitions, Nexans aims to step up its ascension in the value chain while continuing to provide innovative solutions to its partners.

Managing Director, Nexans North & West Africa

Find all our press releases

Read all