A pure player in electrification and pioneer in the energy transition

Stretching back to the late 19th century, we have always played a key role in electrification.

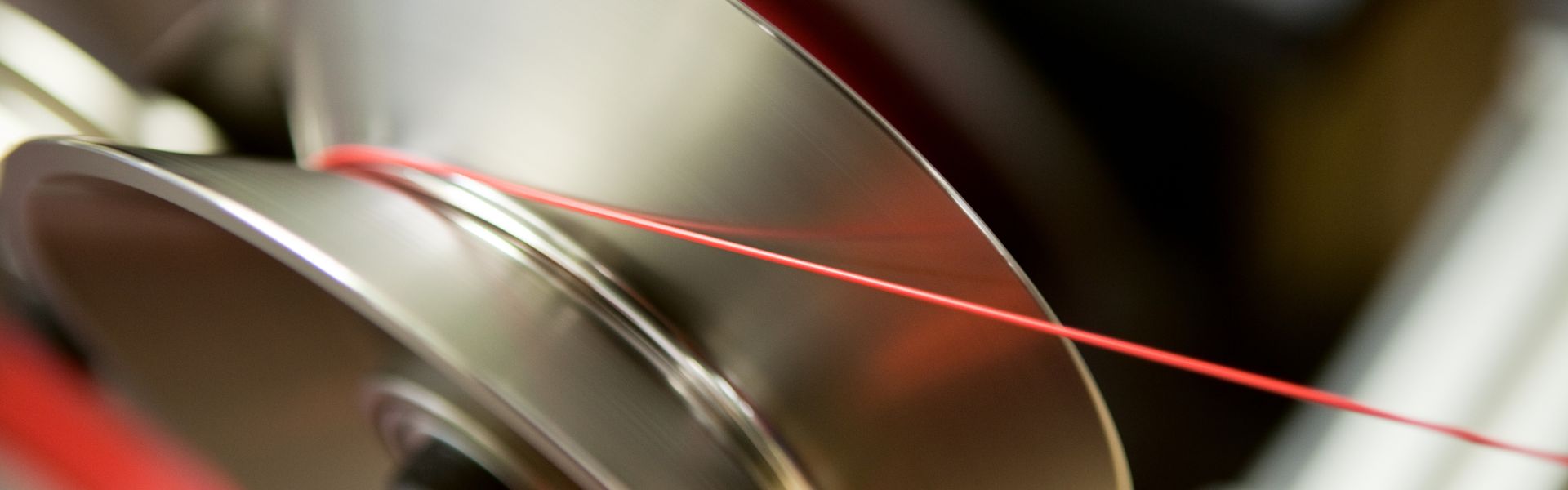

Our cables are essential for all types of electrical transmission, meeting the needs of big cities as well as contributing to the development of remote villages. So, it is only natural for us to be leading the way towards an all-electric future and contributing to the general effort through our vision and innovations.

Our strategy is to set new standards in safety and sustainability for the future as part of a rational approach. We want to lay the foundations of a world that shows greater concern for both the environment and for people.

Changing course

In 2018, we made a strategic shift in our approach to refocus on what we do best: electrifying the world.

Intervening throughout the chain

We play an essential role in operationalizing the various links in the electrification chain, from power generation to transmission, distribution and usage. Present in over 40 countries, we prefer local sourcing for local markets.

Paving the way

We have always been committed to electrifying the world. Thanks to our unique management model, we are agents of change. We are paving the way for economic performance to be intrinsically linked to the environment and human commitment.

Our strategy

Rationalization to drive performance

Rationalization to drive performance

We have replaced volume and complexity with value creation and simplification.

We have taken a number of steps to streamline our organization and create value:

- Scaling down from 25 areas of activity to four main business units, and from 17,000 customers to 4,000 strategic customers.

- Looking beyond cable supplies alone to take up a central market position delivering services and solutions. Through partnerships with our strategic customers, developing new solutions and services tailored to their needs.

- Continuing to cover the entire electricity value chain, from generation and transmission to distribution and usage. We are a global specialist and market leader at every stage: high voltage, medium voltage and low voltage.

Between now and 2040, demand for electricity is expected to rise by 40%. We have a role to play at the very heart of the electric revolution, supplying renewable and decarbonized energy in an increasingly circular economy.

To this end, we are already supporting major projects, making it possible for wind farms to power megacities such as New York (USA). We are taking all possible steps to promote a new industrial approach, factoring in any potential shortages of raw materials. Today’s copper or aluminum scrap will provide a basis to develop the markets of tomorrow.

More information

95%

of Nexans’ sites have received environmental certification.

100%

of production sites are ISO 14001 certified.

100%

of sites will be certified by 2030.

Our new E3 management model: sustainable performance

Most of today’s management models are based on theories dating back to the late 1980s, for the most recent among them. But times have changed. We are entering a global permacrisis, an era in which environmental, social and economic crises are stacked one on top of the other. Companies increasingly find themselves facing a double bind. Clashes between environmental, financial and social considerations create structural challenges. To overcome them, we need a radical rethink of our management style.

We see three factors as essential and interdependent in navigating this new world:

- Economy

- Environment

- Engagement

All three underpin our new management model, E3.

In the absence of theoretical models or literature on the subject, we developed our own model based on one simple principle: to manage all our sites in accordance with the three above criteria, considering each one as equally important.

Our vision of management considers ecological performance, business performance and employee well-being as indissociable.

This rational and balanced approach has become the driving force behind our profitability.

In 2022, we rolled out the E3 model across the Group. Today, all our sites and major projects are adopting this unique method.

From a structural standpoint, the new model does away with the cost of complexity, allowing us to focus on our core business as ultra-specialists in electrification. And the results are there to see. We are generating profits with a low-carbon energy impact. Our employees are proud of this. And herein lies the systemic strength of E3.