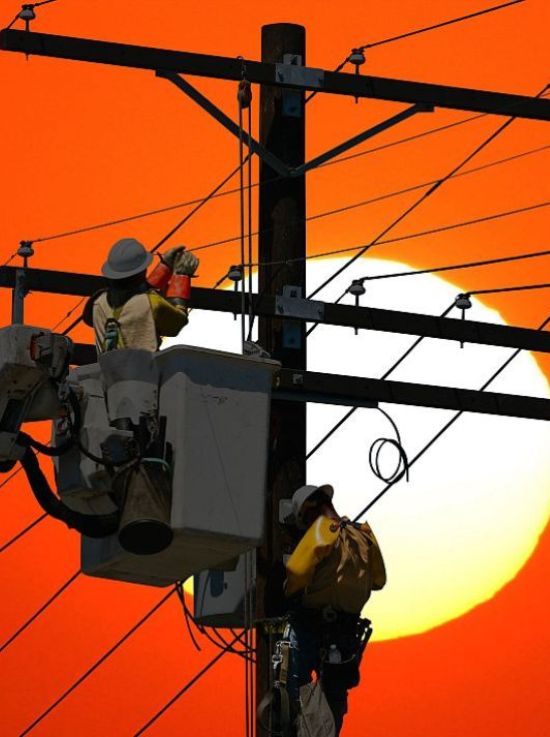

To limit the impact of climate change, society is moving towards an energy model based on renewable energies. As a pure player in electrification, we are at the heart of this transition, and we have already incorporated the principles of sustainable development into our strategy. Our solutions contribute to creating more virtuous solutions that better reflect environmental realities.

Nexans solutions: sustainability, performance and engagement

Developed in 2021, our new performance model – E3 – shows that rationalization and environmental optimization strategies are powerful profit generators. The results are conclusive, and our achievements illustrate our success in terms of engagement, environmental performance and business performance.

Given our area of business, we have always been committed to a more sustainable future. We are therefore aware of the role we have to play in the energy transition. For this reason, we are working to accelerate the deployment of renewable energies, which are essential to meeting net zero targets.

We are involved in projects to build, expand and modernize wind and solar farms, renovate power grids and interconnectors, and develop electrification projects in emerging countries, as well as to implement low-carbon solutions for networks and applications, urban mobility and digitalization.

In 2025, the Group takes another step forward by introducing 10% recycled aluminum into all low-voltage cables produced at its Jeumont plant in northern France. By combining low-carbon energy with recycled raw materials, we are reducing our own carbon footprint while helping our customers achieve theirs. This initiative is part of our circularity strategy, ensuring responsible use of resources and reinforcing our commitment to building a sustainable, resilient and efficient electrification ecosystem.

Making decarbonization a central concern

We set our carbon goals for 2030 using the GHG protocol calculation method. In this way, we are in line with the Paris Agreement to limit global warming to + 1.5°C compared with pre-industrial levels.

We are committed to achieving carbon neutrality by 2050, and have confirmed this commitment with the Science Based Targets initiative (SBTi), which has validated our target of a 46% reduction in Scope 1 and 2 emissions and a 30% reduction in Scope 3 by 2030 (base year: 2019). Our carbon footprint is primarily linked to scope 3 emissions, notably the use of sold products, which accounts for over 94% of emissions in this scope.

We are working across the entire supply chain to combat climate change.