1. Deep sea grid interconnections – from megawatts to gigawatts

The interconnection of grids is not only reaching impressive depths, but their capacity has also gone from hundreds of megawatts to gigawatts.

To date, the deepest installed HV cable system is the SaPeI interconnector, stretching 435 kilometers, linking Sardinia and mainland Italy, reaching 1,640 meters below sea level.

One revealing example of this revolution is the Tyrrhenian Links project, currently under construction. It will connect Sicily with Sardinia and the Italian peninsula. It will be installed at a record-breaking 2,200 meters deep, for a transmission capacity of 1,000 MW. Achieving this is possible thanks to advances in high-voltage direct current (HVDC) systems, which can transmit larger amounts of power over long distances.

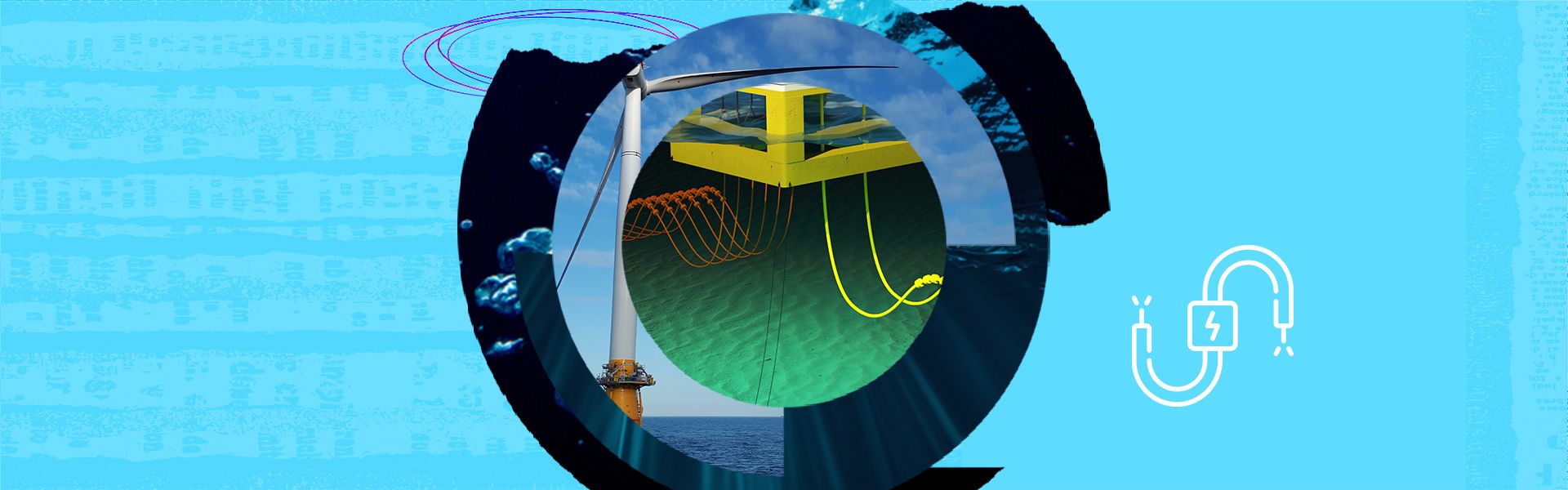

If this technology is already available for shallow waters, engineering challenges arise when increasing the water depth.

2. Mass-Impregnated (MI) undersea cables – decades-long reliability track record

Mass-impregnated cables’ first commercial use was in 1954 for the Gotland HVDC Link to connect the Island of Gotland to mainland Sweden. Since then, mass-impregnated cables have been the primary choice for subsea HVDC interconnector projects requiring voltages surpassing 500 kV over long distances and extreme depths.

Simply put, a MI undersea cable is a type of HVDC cable specifically designed for underwater applications. Here is the breakdown:

- Construction: it is made with layers of high-density paper tapes wrapped around the conductor. These tapes are then impregnated with a special, high-viscosity compound. This compound is key – it’s thick and doesn’t flow easily, even if the cable is damaged.

- Application: it is used for transmitting large amounts of electrical power over long distances underwater. They are particularly useful for applications exceeding 500 kV DC and long distances.

MI cables offer three main advantages that make them innovative for undersea applications:

- Reliability: The high viscosity compound prevents leakage even if the cable is damaged, making it more reliable for underwater use compared to older designs.

- Durability: cables installed decades ago are still operational today, demonstrating their long lifespan.

- Depth capability: they can be used for extreme depths with proper design features.

Overall, MI cables are a well-established and trusted technology for transmitting large amounts of power underwater, making them a key innovation for subsea power transmission.

Breaking even new barriers to deep sea cable depths will be the Great Sea Interconnector project. Reaching depths of up to 3,000 meters in some areas, the project will connect Israel, Cyprus, and Greece via Crete. Stretching 900 kilometers from Crete to Cyprus, the 1,000-megawatt, bi-pole cable will bolster energy security and facilitate electricity exchange between the countries.

3. Overcoming subsea cable challenges – new design approaches

The main challenge in using MI technology in subsea cables however is the elongation of the insulation system during deployment and retrieval.

There are many ways this can be overcome. The most prominent is through cable design, conductors, materials, or installation methods.

Additionally, 500+ kV extruded cable designs are also being developed. A major advantage of extruded cable design is its ability to sustain greater elongation compared to MI cables. A challenge for extruded design is the need for effective water blocking in the conductor in the case of damage to the cable. At 3,000 meters below sea level, the pressure is so great that if the water is not blocked in the conductor, it can easily penetrate tens of kilometers into the cable, leading to costly repairs.