Decarbonizing hydrogen

But just how virtuous is hydrogen? Its production processes vary wildly in their environmental impact, leading to the informal and sometimes bewildering hydrogen rainbow classification system. The vast majority of hydrogen today comes from fossil fuels via high temperature steam reforming of methane, with 10kg of CO2 emitted for every kilogram of H2. This type of production is responsible for 2-3% of global CO2 emissions, on a par with air-travel!

Making hydrogen is also possible using electrolysis. This process, that splits water molecules into oxygen and hydrogen, is energy-intensive – 50-60 kWh generates 1kg of hydrogen. But when the electrolyzers are connected to renewable energy sources, very low-carbon hydrogen can be achieved.

However, its low density at room temperature means it must be compressed at high pressures – up to 700 bar – or cooled to a very low temperature – -253°C (20K) – to turn it into a liquid that can be transported and stored.

Furthermore, the carbon intensity of hydrogen produced by water electrolysis depends on the energy mix of the electricity source. In some countries with lots of coal power plants, the carbon footprint of electrolysis process could be more detrimental than steam methane reforming.

High-pressure challenges

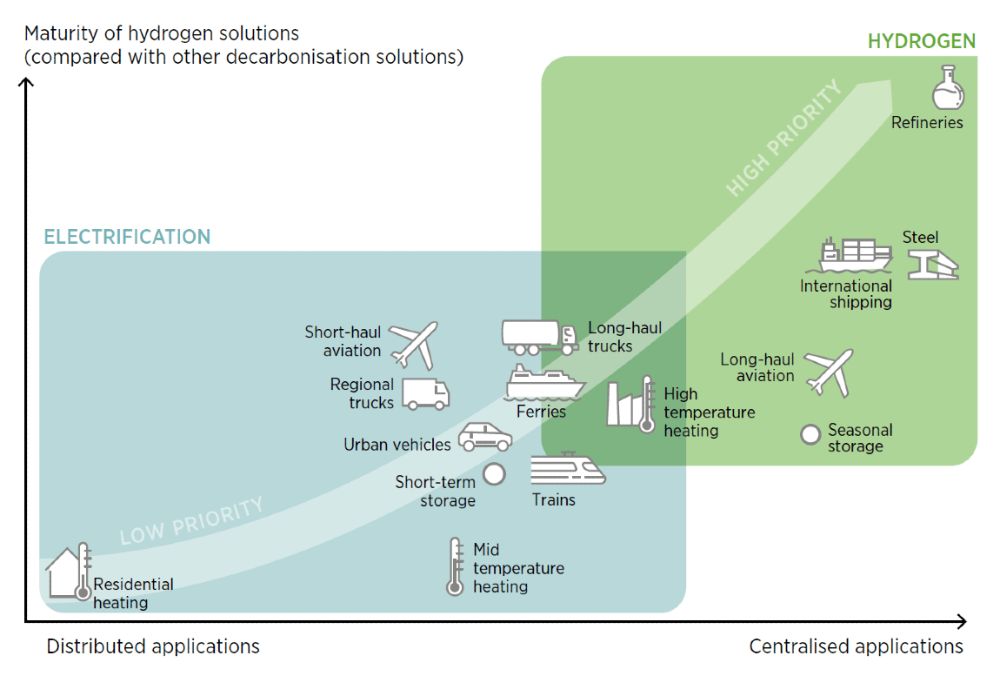

New applications for hydrogen are springing up in the fields of energy and mobility. But to ensure the boom doesn’t run out of gas, big changes must be made over the whole lifecycle.

This starts with production. For hydrogen to truly contribute to a net zero emission world, the energy used for the electrolysis must come from renewable sources such as onshore or offshore wind and solar farms which Nexans already connects. This will have a direct impact on hydrogen’s price tag, which will then be driven by the costs of electricity and capital investment in farms and electrolyzer units.

Once it has been produced, all this hydrogen still has to reach the end user, and the right storage and transportation solutions could mean the difference between success and failure. Just one kilogram of hydrogen takes up 12m³ at atmospheric pressure, and very high pressures (up to 700 bar) are needed to bring this volume down to manageable levels.

The solution? Liquefy hydrogen. This has been a practice in aerospace for decades, and new applications for liquefied hydrogen (LH2) are emerging, such as:

- Overseas transportation of energy between production and consumption places. The Hystra project – producing hydrogen in Australia and shipping it by cargo to Japan – was a world first, enabled by Nexans high-flexibility cryogenic transfer lines. Projects aiming at deploying the infrastructures for maritime transportation of LH2 are now starting in key maritime ports to prepare the forthcoming worldwide trade of LH2.

- Aeronautics. Airbus is aiming to fly the first commercial plane fueled with LH2 in 2035. This will mean a complete change of airport infrastructures to supply hydrogen, electricity and sustainable aviation fuels, in places where safety and floor space are major stakes.

Innovation at every stage of the game

Nexans is contributing new technology and business solutions all the way down the hydrogen value chain.

- On the production side, we provide solutions for optimizing the operating and capital expenses of producing renewable energy. Applied to electrolyzing units, our unique know-how on grid design could help achieving optimized hydrogen production facilities

- On the storage and distribution side, Nexans has long been a pioneer in supply infrastructures for cryogenic fluids. Our vacuum-insulated flexible transfer lines offer easy-to-install, safe and reliable solutions for tank-to-tank transfer of LH2. Their “plug-and-play” installation is as easy as laying a power cable and beats conventional rigid piping systems when it comes to speed of implementation. We recently equipped the world first loading systems for ship-to-shore transfer of LH2 in Kobe, Japan, with long length, high flexibility cryogenic transfer lines capable of high flow rates, numerous bending cycles and minimal boil-off.