Here are 4 areas where AR is poised to make an impact:

- Error Prevention: By overlaying digital data on physical environments, AR can prevent human errors in cable installation and maintenance. It ensures that each task is performed with exacting precision, avoiding costly mistakes and rework.

- Real-Time Problem Solving: Field technicians can use AR for immediate assessments of critical infrastructure. Whether it’s identifying faulty connections or conducting routine maintenance, AR provides real-time insights, minimizing downtime and improving overall reliability.

- Remote Assistance: AR could allow experts to guide field workers remotely, offering live feedback as they troubleshoot issues on-site. This could drastically reduce response times and the need for expert travel, particularly in rural or hard-to-reach locations.

- Enhanced quality and durability of installations: AR allows connections to be systematically checked. Furthermore, documentation is digitized, which improves maintenance. Digital assistance can also be systematically provided, fundamentally changing how installers are trained to use connectors and cables.

Given these potential applications, it’s clear that AR could change the game for electrification. And one innovation leading this charge is Infracheck – a solution that promises to revolutionize how cable management is handled.

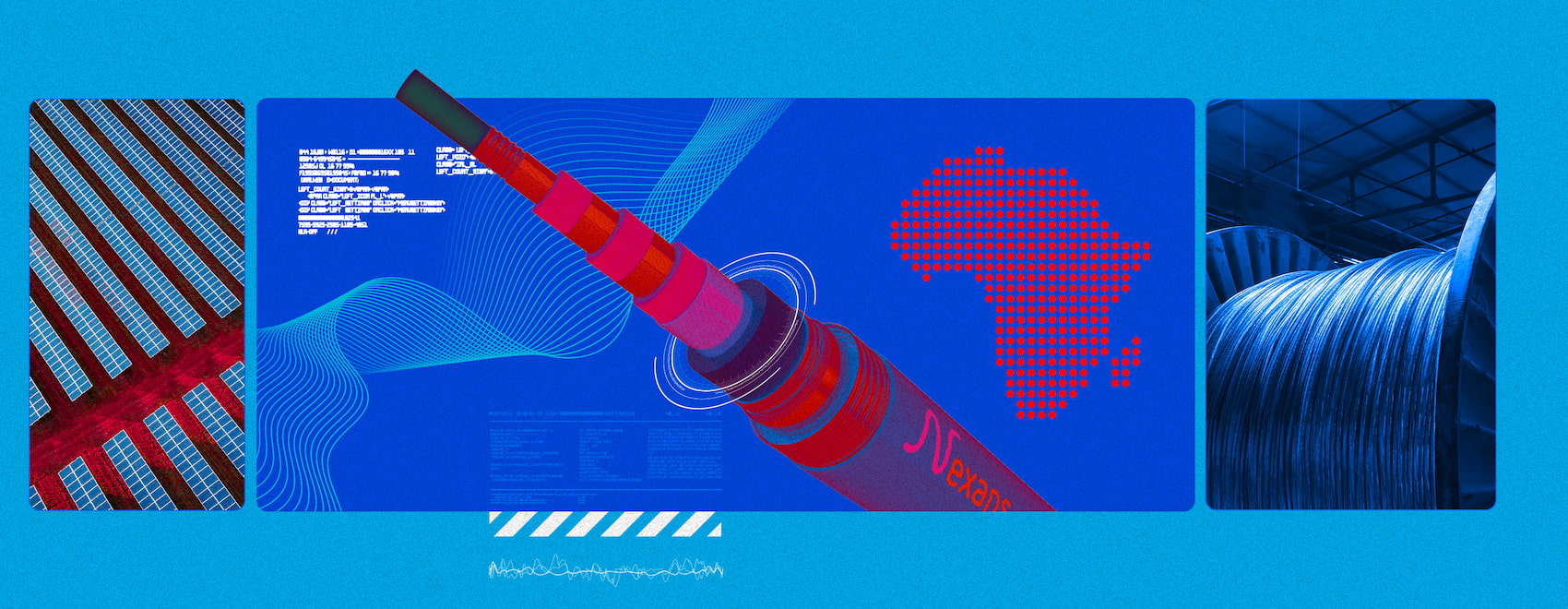

Infracheck: Redefining Cable Management

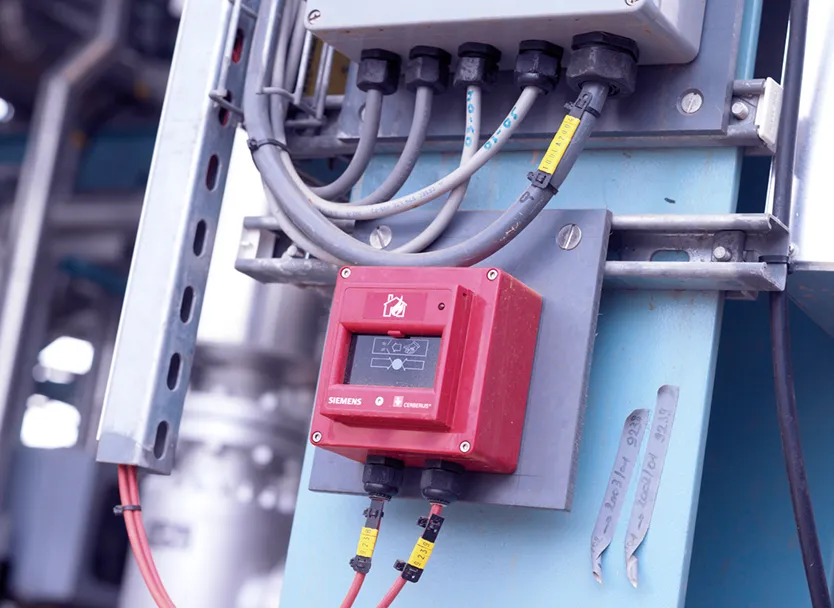

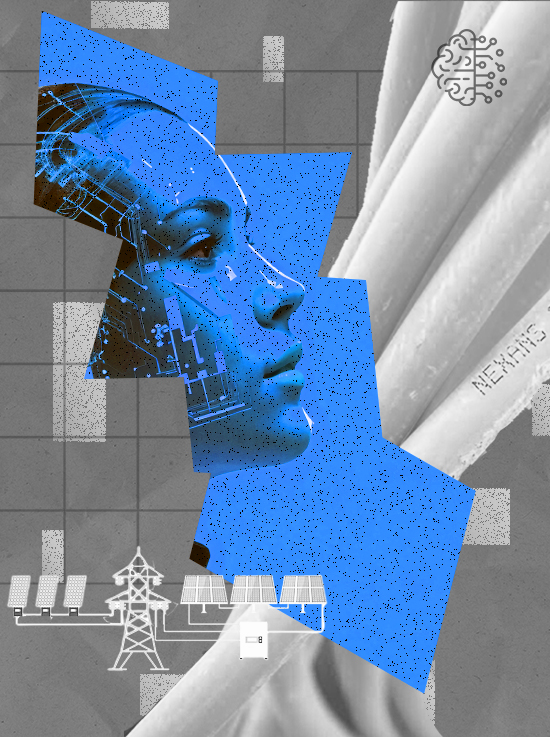

Infracheck, developed by Nexans, marks a significant advancement in cable management through AR technology. This innovative tool allows technicians to verify cable connections instantly using a smartphone or tablet. By capturing images of cable installations, Infracheck overlays real-time data, offering immediate assessment of conformity with technical and safety standards.

The solution’s user-friendly interface makes it accessible for technicians at all experience levels, reducing human error and ensuring precise results. Infracheck not only streamlines the verification process but also minimizes the need for rework, ultimately saving time and resources while enhancing the reliability of critical infrastructure.

With Infracheck, technicians gain the ability to resolve issues on the spot, ensuring high performance and reducing system downtime – a crucial benefit in the electrification industry.

The Future of Electrification: Powered by AR

As AR continues to gain traction across industries, its impact on electrification is becoming more evident. The blend of real-time digital data with physical infrastructure is transforming how we think about everything from cable management to grid maintenance. In a sector where reliability and precision are paramount, AR is providing the tools needed to meet these challenges head-on.

The implications for the future are vast:

- Enhanced Training: AR could revolutionize how technicians are trained, offering immersive simulations that allow them to practice installations and repairs in a safe, controlled virtual environment.

- Improved Safety: AR can also enhance safety by providing technicians with real-time alerts and warnings about potential hazards during installations or repairs, reducing the risk of accidents.

- Faster Maintenance: With AR-guided systems, maintenance work can be carried out more quickly and accurately, minimizing downtime for critical infrastructure and keeping systems running smoothly.

The electrification industry is on the cusp of a digital transformation. With tools like Infracheck paving the way, AR is set to become an indispensable part of ensuring that our power grids remain efficient, reliable, and future-proof.

A New Era for Electrification

AR is no longer a futuristic concept. It’s here, making industries more efficient, safer, and smarter. From improving the assembly of aircraft to enhancing medical procedures, AR is transforming the way we work across the board. In electrification, the potential for AR is immense, offering real-time precision and reliability where it’s needed most. With innovations like Infracheck leading the charge, augmented reality is unlocking the future of electrification—one where infrastructure is not only reliable but also smarter, safer, and more efficient.

The digital and physical worlds are merging, and AR is at the heart of this revolution. Electrification, as we know it, is entering a new era – one where augmented reality drives the future of how we power the world.