Superconductivity is currently the subject of intense interest and debate, fuelled in particular by research into superconductors at ambient temperature and pressure, the discovery of which would trigger a technological revolution. The many questions raised by this work are reminiscent of the scientific challenges researchers had to overcome when they discovered high-temperature superconductors in 1986. A look back at this crucial technology for the cable industry, exploring recent advances, persistent challenges, but also how Nexans is providing the world’s very first superconducting cable system integrated into a rail network.

As we move towards an all-electric future, the need to increase power supply in cities becomes ever more urgent. Equally important is the need for resilience: as electricity becomes the main source of energy, supply will need to be 100% reliable. Downtime is not an option.

Why superconductors?

Superconducting cable are electrical connectivity miracles. They have unique qualities that make them perfectly suited to modern, high-capacity electrification projects in cities.

First, superconducting cables can carry extraordinarily high currents – far greater than conventional copper or aluminium cables. This makes it possible to transmit and distribute electricity at relatively low voltages. In practical terms, this means there is less need for substations in city centres – a major cost saving.

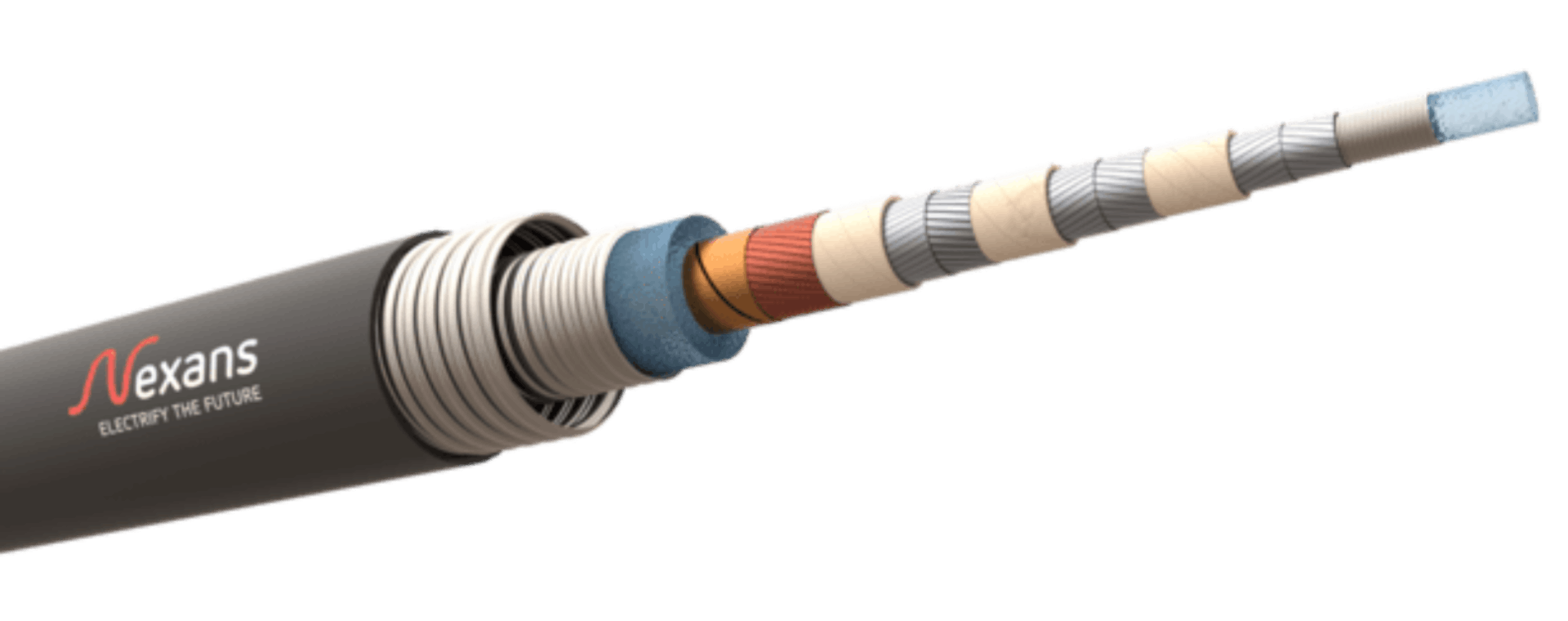

Second, superconductors can transmit a huge amount of power relative to their size. For example, a single superconducting cable with a diameter of just 17 cm can transmit 3.2 GW – enough to power a large city. Corridors for superconducting cables can be as narrow as one metre, meaning they can be deployed with minimal disruption.

Third, superconducting cables do not produce heat and can be fully shielded on an electromagnetic standpoint, so there is no interference with power, telecom and pipe networks which typically criss-cross cities. Many of the constraints that govern cable routing do not apply when superconductors are used.

On top of this, superconductors are incredibly efficient. Superconducting cables have extremely low resistance when an AC current is carried and no resistance when the current is DC, so losses are minimal.

A first for rail

Nexans is working with SNCF, France’s national rail company, on a pioneering project to boost power supplies to Montparnasse station in Paris using superconducting cables.

Montparnasse is one of the busiest railway stations in France and handles more than 50 million passengers a year. This figure is expected to exceed 90 million by 2030. Handling new demand will require extra trains – and extra power.

As with any city-centre power upgrade, the big challenge at Montparnasse was finding a way to bring in a new power supply without the need to dig up the surrounding roads – which can be a long, expensive and disruptive process.

Fortunately, the existing cable route between Montparnasse railway station and the substation that serves it had spare conduits available. Unfortunately, there were only four of them. Using conventional copper cables to deliver the required power would require a dozen of cables. What could be done?

Superconducting cables are the answer. Nexans’ solution uses just two cables, each less than 100mm in diameter so they can be easily threaded through the existing conduits. Despite their small dimensions, each cable is capable of handling 5.3 MW, or 3500 A at 1500 VDC – a huge amount of electrical energy.

What makes this project so significant is that it is the first-ever use of superconducting cables in France, and the first time superconductors are integrated in a railway grid anywhere in the world. The new power supply at Montparnasse will be commissioned in 2023.

What does the future hold?

The Montparnasse project underlines the massive potential superconducting cable systems have for boosting power supplies in cities – particularly where site constraints place limits on the use of conventional copper and aluminium cabling.

Rail transport aside, superconducting cable systems are likely to play a bigger and bigger role in satisfying the rising demand for electricity. This is being driven by new commercial uses – such as data centres – and by new sources of domestic consumption, which include electric vehicle charging, heat pumps and air conditioning.

In addition to meeting increased demand for bulk power, superconducting systems will play a critical role in boosting the resilience of urban electricity networks.

The Resilient Electric Grid (REG) project in Chicago, USA, underlines the direction of travel. Nexans designed, manufactured and installed a superconducting cable for the REG system, which helps to prevent power outages by interconnecting and sharing excess energy capacity from nearby substations, and by preventing high fault currents.

Nexans is the global leader in superconducting cable systems. Our unique capabilities in R&D, innovation, testing, manufacturing and deployment mean that we are perfectly placed to assist our customers, partners and stakeholders as they prepare to electrify the future.

The Internet of Things and connected objects: the stakes ahead

By 2030, there will be 30 billion connected objects worldwide, including 244 million in France, according to estimates by ADEME (the French Agency for Ecological Transition) and Arcep (the country’s electronic communications authority). Some will be everyday objects, others will be used in professional applications.

The Internet of Things (IoT) is briming with development potential and exciting possibilities for homes and businesses. As it expands, the IoT also brings new innovative solutions for electrification. It will help industrial companies increase their productivity and help people reduce their energy consumption at home. And it is growing 15% to 20% a year across the board.

Let’s deep dive into the IoT concept, the prospects for harnessing electrification, and the issues and challenges surrounding it.

The Internet of Things: how does it work?

The IoT is a network of connected devices with built-in microprograms, sensors and connectors enabling them to interact with the Internet. Examples range from household appliances to electricity meters and on to cable drums.

The IoT, in a nutshell, makes things smart. They can collect data, process it onsite and share it online or with other devices to analyze it in more depth. Then they can take measures to improve operations or automate tasks.

When you transfer data online, you can build an intelligent ecosystem where you can use devices in more sensible and more modular ways. You can upgrade a home into a smart home, a city into a smart city and a grid into a smart grid. In France, with 35 million smart meters, electrification is among the sectors that have reached the most advanced stages of digitalization with the IoT. And it will reach even further as Enedis, which operates the country’s electricity distribution system, has announced plans to install 250,000 sensors throughout its grid over the next 5 years.

The possibilities on the operation side are opening up numerous opportunities. For example, home automation environments will be able to manage energy consumption. For connected objects to communicate effectively, however, they need specific systems. These include radio-wave modules, sensors, cellular routers and gateways, and they are all essential to manage data flows and tackle the related challenges.

IoT and innovative electrification solutions

The IoT is bringing in an array of electrification solutions that create value in homes and companies:

- Managing energy consumption: the IoT can help consumers keep an eye on their energy consumption and manage it more efficiently using real-time electricity and gas meter readings. Smart connected objects can also be programmed to switch off automatically when they are not being used, which also reduces energy costs.

- Monitoring equipment: companies can use the IoT to monitor their solar panels, wind turbines and other systems remotely, to make sure they are running properly and optimize their output.

- Storing energy: the IoT can also help to monitor and manage storage levels, and optimize battery charging-discharging cycles.

- Reducing costs: the IoT can also help to reduce operation and servicing costs by enabling predictive maintenance, shortening downtime, and optimizing supply chains and use of resources.

- Optimizing grid operation: the IoT does this by tracking demand for energy in real time and adjusting supply accordingly, which can help to reduce power production costs and optimize distribution.

Issues and challenges around connected products

There are several practical and economic issues and challenges surrounding IoT operation.

IoT communication

When you have objects scattered around the globe, the first challenge is to interconnect them. Some of them may be in city centers, others may be in out-of-the-way places that telecom networks barely reach. To tackle this challenge and improve scalability, Nexans uses a variety of communication protocols and teams up with telecom operators worldwide.

Then you must integrate the routers, sensors and other devices mentioned earlier. Three main notions come into play in IoT rollout:

- the reach of the equipment and connected objects you use;

- energy consumption;

- bandwidth requirements and capacity.

In other words, you must adapt the available resources to match the complexity of the infrastructure—and that infrastructure can span a local area, a country or the globe. That is why it is important to partner up with other experts, as Nexans started doing with Orange in 2020.

Cybersecurity for the IoT

Cybersecurity is as central to the IoT as its efficiency. The more connected objects, the greater the risk of cyberattacks, because the objects collect sensitive data and can provide hackers with a back door into a company’s information system. The entry point can be a computer as much as a connected object.

Even something as simple as a camera can be a way into the core system. A casino in London, for example, was hacked through an Internet-connected fish-tank thermometer linked to the rest of the system. Ironclad security protocols are an absolute must for the IoT: a device can be a risk however harmless it may seem.

The IoT business model

Large-scale IoT rollout is viable even when you factor in all the complexity associated with integration. It for instance provides several advantages in industrial production and supply chains:

- smoother goods flows and real-time monitoring and updates;

- more efficient collaboration between departments;

- better goods tracking and transit;

- swift and secure data collection;

- tighter control over stock.

Besides all of the above, customer service teams can respond faster, especially when they have to deal with delivery delays or other problems.

Ultracker: the Nexans solution to optimize supply chains

Here at Nexans, we have developed Ultracker, a pioneering digital solution to harness the possibilities in the data collected by IoT sensors, combined with artificial intelligence and cloud storage.

With this solution, our customer installers and utilities can:

- optimize their working capital and logistics flows;

- shrink their carbon footprint by shortening drum rotation cycles;

- reduce losses and prevent cable theft.

The IoT trackers embedded in our cable drums and transportation fleets, and our cable-related products, enable customers to track drum status more closely, see a clearer picture of their stock levels and supervise jobsites remotely. This cuts raw material and supply wastage.

Nexans’ IoT expertise, and the solutions we have set up with our partners enable cable system and cable life cycles management, range from delivery on site to measuring how much cable there is left on a drum before pick-up. A leading European electricity distributor that adopted Ultracker to monitor its cables via the IoT is saving over €1 million a year.

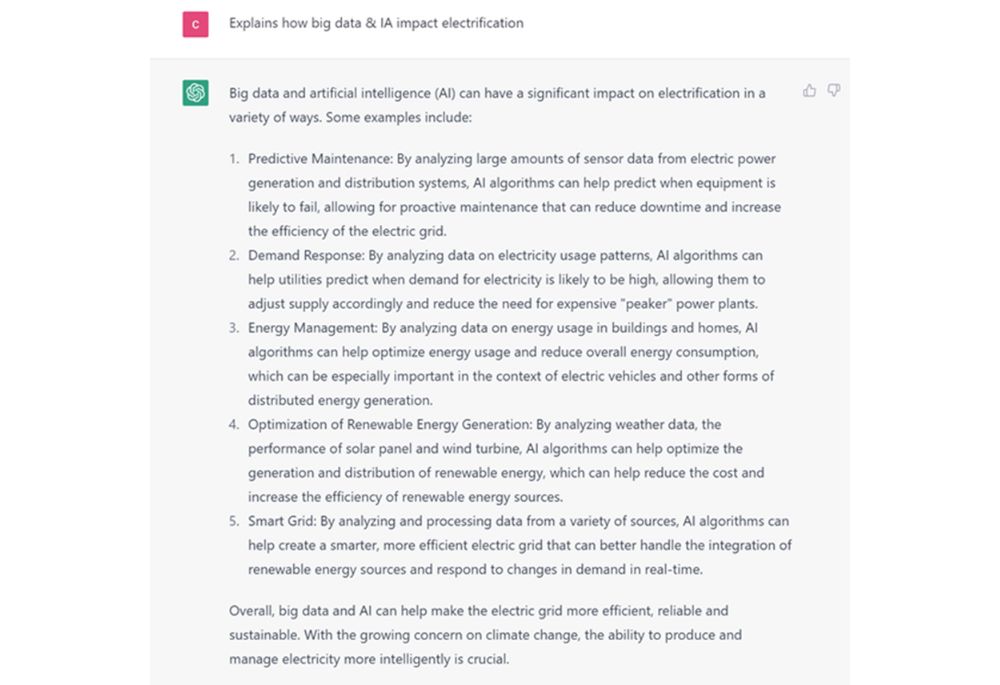

Artificial Intelligence (AI) has been around for a while. The first models date back to the 70s but these concepts remained theoretical until we were actually able to teach computers to think for themselves. Today, Artificial Intelligence is everywhere. It allows computers and cloud connected devices to reproduce human-related behaviours such as reasoning, planning and creativity. Artificial Intelligence is primarily dependent on the quantity of data it is given. This is where big data plays an active role. With the increased collection and analysis of digital data, big data and AI are now emerging as rich areas of opportunity for electrification professionals.

Electricity 4.0 : Big data and AI for smarter power management

Big data is a major trend in the energy industry. The Electrical network become smart grid due to Data collected from a variety of sources, such as smart meters, sensors, twin digital. Once stored, this data is an invaluable resource for the industry to make better decisions about energy production and consumption.

Electricity was deployed extensively in the late 19th century, which was the First Wave of Electrification from 1880 to 1920. This period saw the widespread adoption of electrical power in industry and the development of the first electrical grid. Then the Second Wave of Electrification took place between 1920 and 1950 with the expansion of the electrical grid into homes and the development of new electrical appliances such as refrigerators, washing machines… During the third wave of Electrification from 1980 to present, we have seen the growth of the digital revolution and the development of new technologies such as computers, the Internet, and mobile phones.

Today the fourth wave of electrification so-called Electricity 4.0 is characterized by the integration of digital technologies such as Artificial Intelligence (AI), the Internet of Things (IoT), and advanced data analytics into the electricity infrastructure.

The aim of Electricity 4.0 is to create a smarter, more efficient, and more sustainable electricity system that can respond to the fast changing demands (+20% by 2030, +40% by 2040).

Electricity 4.0 is expected to optimize the use of existing assets, integrate renewable energy sources into the grid, increase energy efficiency, reduce greenhouse gas emissions, improve grid stability, reduce costs for customers and provide more reliable and flexible energy services to customers.

Moreover, generative AI and adjacent models are changing the game. Indeed, support technology reaches a new level, application development time is reduced, and powerful capabilities are brought to non-technical users.

Just recently, we saw the buzz around ChatGPT and what it can achieve. For instance, if we ask the question “how do big data and AI impact electrification”, we have to admit ChatGPT answer might not be perfect but is still very impressive.

These technologies will definitely have an impact on the world of electrification. But AI is mainly dependent on the quantity and quality of the data that will be used to learn. Big data provides the storage and processing capabilities necessary to educate the AI by feeding it with a lot of information.

Machine Learning and AI are the winning combo to efficiently exploit big data. This involves identifying patterns via data mining and data science more generally.

Big data: The cloud has won

In the age of big data, the famous wave 2 of “move to cloud” announced by providers is underway and is accelerating. As a reminder, the first phase of a migration to the cloud is a discovery phase that allows to analyze the strengths and weaknesses of an infrastructure and to determine future needs.

The number of detractors is getting smaller every day, privacy and sovereignty issues are both solved by the strategic commitments of clouders and swept away by the ease of use… All sectors – banking, telecoms, insurance, etc. – are rapidly adopting cloud-hosted big data solutions.

The first paradigm shifts are appearing in the world of electrification, driven in particular by operators such as Total Energie or Schneider. We can also note the predominance of the estimated Azure services of Microsoft Vs Aws of Amazon in the field of public cloud related to big data.

Exploring the challenges of generative AI and Big Data in 2023

Generative AI promises to make 2023 one of the most exciting years for AI and, by extension, Big data!

Keep in mind that ChatGPT’s prowess is based on the net recorded in 2021, but, as with any new technology, we must always proceed with pragmatism and measurement, because the technology now presents many challenges:

- Ethics: what sovereignty for data? What protection for personal data? What commitment to transparency and readability by the players?

- Environment: AI and Big Data are a paradox in that they are both a solution for optimizing energy consumption and resource mobilization, but also a cause of this increase;

- Cybersecurity: AI and Big Data in the field of energy is largely based on measuring instruments, therefore on IOT, offering an ever increasing security surface;

- Business Model: if the value of AI in the energy field is no longer to be demonstrated, the business model associated with services is very complex. For example, if we take the residential segment, the Chat GP virtual assistant has made the buzz as has Amazon with the announcement of a massive layoff, including the Alexa division (Amazon’s virtual assistant), in the same week;

- Talents: the development of digital services requires the onboarding of excellent technical skills, but not only. It’s the entire operating model that needs to be rebuilt. The human dimension is one of the biggest challenges brought by AI and Big Data: attractiveness, meaning of work, conditions, etc.

Big Data analysis combined with artificial intelligence also involves various risks. Key concerns include unintended consequences of automated decision-making, increased risk of cyber-attacks due to reliance on technology, inaccurate predictions leading to poor decisions, over-reliance on algorithms instead of human judgement, lack of transparency in the development process, etc…

AI and big data for Nexans

As previously expressed, AI in the energy domain is most often carried by a phygital system, meaning software + hardware.

To this end, an important part of our work in terms of AI and big data concerns the implementation of learning based on neural networks. The latter’s role is to translate images or text from measuring instruments (thermometers, drones, etc.) into numbers. The aim of these approaches is to understand recurrences, date them, predict them and locate them. We are in the AI for grid sensing.

One of the important activities in the field of electrification is the monitoring of networks for all segments: generation, transmission, distribution and use of electricity in buildings and industries. this requires the development and implementation of sensors that measure electrical activity along the value chain.

This is already the case in developed economies at home or in industry with Smartmeters. High voltage transmission lines are also systematically monitored for temperature and voltage. Medium-voltage electricity distribution networks and the connection networks of distributed renewable energies are less frequently monitored.

It is therefore essential to obtain data on the entire electricity deployment chain.

A second important activity is the analysis of data in order to optimise products or systems. this is at the heart of artificial intelligence and Big data.

In technical terms, we mobilize the techniques developed essentially for the field of natural language processing with recurrent neural networks and more precisely convolutional neural networks. In other words, the technology stacks of ChatGPT & DALL-E.

A long-term energy transition

Big Data is a hot topic with huge implications for the energy sector. It is a powerful tool that can be used to improve the efficiency of energy systems, production and consumption. In addition, it can also be used to improve electrical networks and smart technology.

Thanks to Big Data, it is possible to explore various scenarios and objectives related to the energy transition. In particular, this technology makes it possible to analyze how different systems and supply sources are interconnected and how they could be optimized in the long term. Thus, it offers an invaluable perspective to achieve a certain autonomy in a long-term energy transition objective.

The 3S (smart, small & selectivity) are challenges for the years to come. Addressed in a disorganized way today, they will become the real challenges for AI applications tomorrow:

- Smart data: Understanding and monitoring local ecosystems

- Small data: Limit the use of energy-intensive big data

- Selectivity: optimize the resources needed.

Using digital twins to reduce carbon emissions

First mentioned in 1991 by David Gelernter, the idea of the “digital twin” was first applied by NASA in the 1960s with the Apollo program. It was the space agency that coined the term Digital Twin.

The concept of a digital twin consists in reconstituting objects, processes or physical services in a virtual environment. Its use contributes to improving the design and functionality of systems, optimize their maintenance and diagnose possible problems. Digital Twins have also turned into powerful decision-making tools for strategic planning.

What is the principle behind digital twins?

A digital twin (DT) is a virtual representation of a service or physical object. It ranges from the simplest to the most complex objects such as components, mechanical parts, gears, buildings, cities or electrical networks as big as a country. It also includes the digitalization of industrial processes.

The digital twin generates simulations in order to observe a potential future scenario. The outcomes could change depending on a variety of different factors such as environmental conditions.

The digital twin helps to shorten the duration of the design phase, as well as reduce operating and maintenance costs. The use of digital twins is often combined with other digital technologies, such as the Internet of Things (IoT), artificial intelligence, cloud computing,. Main applications fields are found in industries as diverse as healthcare, aerospace, energy, and automotive.

Product DT

A virtual representation of a single component or a larger set of a physical object, such as a car engine or a road bridge.

Process DT

A numerical view of an entire manufacturing process or a logistics and supply chain flow.

System DT

A generated multidimensional image of a more complex system such as a building or even a city.

Operating possibilities and design of a digital twin

Digital twins are tools available to a wide range of users and many different functions can benefit from their implementation:

- Designers and engineers can build network architectures that are optimized for efficiency and cost, or simulate the resistance of a machine under severe environmental conditions (for example, the behavior of an aircraft turbine vibrating at a high frequency).

- Supply chain and production managers can monitor systems, such as an electrical network, logistics flows, and anticipate malfunctions or failures (for example, they can anticipate the impact over the entire chain of supply of a major disruption of logistics flows or raw material shortage).

- Investment planners and managers can assess the impacts of alternative arbitration scenarios between maintenance opex and investment capex.

Digital Twins rely on three major building blocks:

- Collection & organization of real world data to create the virtual replica. This step is not only based on data but also collects physical equations, modelling when it exists of the interaction between the components of the system.

- Processing by the user of the data through an interface to perform configuration as well as visualize the simulation results and therefore “interact” with the digital twin

- Analytics and computing power made possible by cloud technologies capable of processing massive amounts of data and modeling very complex multidimensional systems and their interactions

As is true with any major digital transformation program, implementing cybersecurity risk assessment routines, mitigation procedures, and a dedicated organization are important pre-requisites before launching a digital twin program.

By 2027, companies and other players in this market are expected to spend up to $73 billion on digital twins, and the market is expected to grow by 30 to 45%. In addition, the digital twins could increase speed to market by 50% and the quality of products offered by 25%.

What are the main advantages of digital twins?

Companies that embrace a dedicated digital twin design strategy can unleash substantial value

- Ability to make more informed decisions in complex environments through a better understanding of the impact on multiple indicators of multiple possibilities. it is a decision support tool that is capable of running thousands or hundreds of thousands of scenarios and analysing their consequences and bottlenecks

- Strengthening risk management by testing mitigation plans to respond to extreme scenarios (for example, simulating the spread of a fire in a building to identify optimal escape routes)

- Ability to react in near-real time to the status of critical equipment (for example by balancing the load of the power grid to reduce or eliminate local congestion)

- Shorter new product development cycles through virtual testing of alternative prototypes, designed-to-cost

- Reduced operating costs through an optimization of the productivity and efficiency of manufacturing lines.

- Improved product quality through real-time sensor monitoring and better control of production process parameters

- Creation of customized services and new offerings and business models: moving from periodic maintenance to predictive maintenance

- Knowledge management and sharing such as the codification of informal, best practices implemented on the shop floor into standard operating procedures

How Nexans uses digital twins for decarbonized electrification?

The world around us, our lives, and our mobility will need to be more electric in the future as electrification is one of the immediately actionable lever to fight and limit the impacts of climate change. The energy grids must be reliable, however, as an electric future will not afford blackouts. The more dependent on the grid we become, the more resilient these systems must also become.

In partnership with Cosmo Tech and Microsoft, Nexans is developing a digital twin solution dedicated to electrical networks. The grid operators will benefit from a powerful software allowing them to reduce their carbon footprint by adopting new investment and maintenance policies while at the same time preserving their profitability by maximizing the value of their infrastructure.

Leveraging real world data, Nexans acts also on the installation, operation, and maintenance of electrical networks.. Leveraging the data from sensors installed on the network, Nexans provides a near real-time view of the areas of congestion on the network and can also detect and localize imminent failures before they occur.

To achieve its objectives in terms of financial, environmental and social dimensions, Nexans has built its own Digital Twin solution E³, a business performance tools that is as powerful as it is unique. This tool measures and monitors the performance on the basis of three KPIs, i.e., Return on Invested Capital, Environmental Return on Carbon Employed, and Return on Skills Employed.

What is the main takeaway of digital twins?

The digital twin brings augmented intelligence to human skills. Its design and deployment use modeling tools, data analytics and lots of computing power to predict different outcomes to scenarios across business. One of the great advantages of digital twins is that they take into account future data, future interactions or equations between components that do not necessarily exist in past data.

Sitting at the crossroads of artificial intelligence, data analytics, and the Internet of Things, digital twins open untapped pools of productivity and performance to a variety of users. From engineering and supply chain managers to c-level decision makers, digital twins move the future forward.

Author

Olivier Pinto is Nexans Innovation Director in charge of services and digital solutions for power grids. He leads a team of grid experts developing a portfolio of innovative offerings designed to solve the issues and address the challenges faced by electrical network operators, leveraging on a solid ecosystem of technology partners. Olivier joined Nexans in 2001 and has held various R&D, operational and sales & marketing positions. He holds a M.Sc. from the School of Chemistry, Physics & Electronics of Lyon, France.

Safe and sustainable electrification is at the heart of our mission

Over 1.1 million fires break out in Europe every year. That’s one fire every 30 seconds. And the human toll is huge: 4,000 fatalities and 134,000 injuries per year. Not to mention the economic impact, with damages running into the billions: in its Global Claims Review 2022, Allianz insurance listed fire as the largest single identified cause of corporate insurance losses, having resulted in more than €18bn worth of insurance claims over five years. Out of those businesses hit by fire, an estimated 70% of them will not restart.

The latest report from the FEEDS (Forum for European Electrical Domestic Safety) shows that more than 25% of fires are caused by electrical failures – mainly due to electric appliances or to obsolete, overloaded installations.

But aging infrastructure is only one part of the story. Accelerated population growth and urbanization around the world mean more people are using electricity every day. At this rate, a 20% increase in demand is expected by 2030, and up to 40% by 2040.

And with new forms of energy use come new risks. From tablets to smartphones, our reliance on electrically powered digital devices is only growing. The rise of new energy usages in building, such as electric vehicles or rooftop solar panels, increases the burden on domestic wiring systems, and the risks related to fire.

This higher electrification has a strong impact: the NFPA (National Fire Protection Association) found out that electrical distribution, lighting, and power transfer equipment accounted for half of home fires involving electrical failure or malfunction. Knowing the devastating impact of fire, such threat requires an adequate answer to protect assets and life.

How do electrical systems contribute to a safer world?

Cables are the electrical backbone of a building, being present everywhere and in large quantities to transport energy and data. They link rooms and floors, go through the walls without interruption, and their number keeps increasing with new energy usages. The fact that they are usually hidden makes it easy to forget their presence. Yet a typical office building will have over 200kg of cables per 100m². It is therefore essential to ensure that cables are as inert as possible when exposed to fire, to avoid spreading flames throughout the building.

In recent years, the emphasis has been on improving fire performance in response to new regulations, such as Europe’s Construction Products Regulation (CPR). Nexans is deeply engaged in this process, working with its partners, customers, and regulation bodies to promote electrical fire safety in buildings, and to adopt higher safety standards at both the national and international level.

Combating fire propagation

Cables do not represent a danger as such, but due to their omnipresence, they can act as fuel for fire and be a vector of flames propagation. A fire that starts in a vertical electrical installation that comprises low-performance cables will reach the first floor of the building in less than three minutes, and will continue to spread with growing speed.

At Nexans, we aim at revolutionizing the safety of buildings, infrastructures and homes, by using our technological expertise to design cables and wires that offer the highest level of performance against fire. Our Nexans Fire Safety offer underlines what can be achieved: thanks to our Low Fire-Hazard cables, smoke emissions, fire propagation and heat release are minimised. Moreover, the cohesiveness of the cable structure is maintained during fire, reducing or eliminating the production of flaming droplets, hence avoiding the start of secondary fires and limiting the risks of injury for firefighters.

All those elements have a major impact on people’s ability to evacuate safely, on time, and with the best possible visibility. In the meantime, low fire-hazard cables facilitate the work of firefighters as they release water when exposed to flame, reducing the fire temperature and diluting combustible gases.

Now a breakthrough to boost the fire performance of cables is in our pipeline. Based on geopolymer technology, this innovation works by creating a hard and hermetic crust around the stranded wires that makes them incombustible. In addition to improving fire resistance, this technology has the benefit of improving the environmental performance of cables by reducing their embodied carbon content – cutting CO2 emissions by 10 to 15% at the manufacturing level.

Smoke reduction during a fire

Smoke and hazardous emissions are the main cause of causalities during an indoor fire, being responsible for 80% of fire-related deaths. Corrosive gases in smoke attack the lungs, as well as the eyes and skin. On top of this, smoke severely limits visibility, making emergency escapes from a building more difficult.

Nexans Fire Safety range is designed to transform fire safety. Our cables minimise smoke emissions, enabling a visibility ten times higher than with traditional designs in the event of a fire – five times higher than the recommended threshold. Furthermore, they reduce the emission of hazardous and corrosive gases, increasing drastically the chance of escape, as well as assisting firefighters as they tackle the blaze.

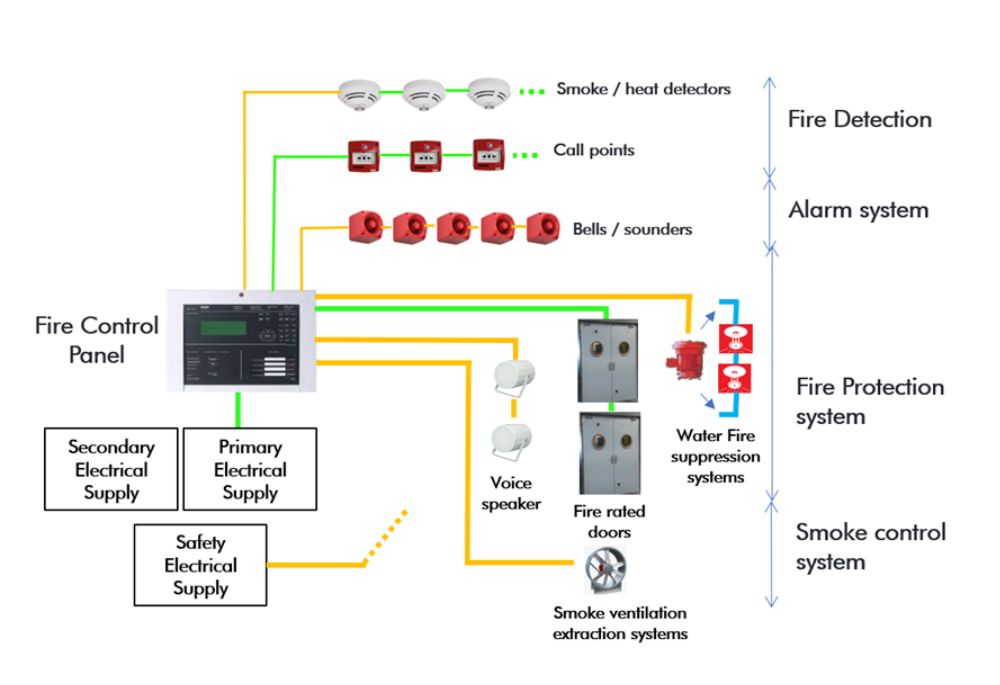

Fire safety systems

Fire resistant cables play a crucial role in maintaining the continuous operation of fire protection and life safety electrical systems – even when a building is on fire. Minimum durations for maintaining electricity supplies in the event of fire are set out in national regulations. Cables must be capable of performing reliably even in extreme conditions, with temperatures up to 1,000°C, and for a duration up to 120 minutes.

Fire protection and life safety systems include:

- Fire detection systems: smoke detectors, heat detectors, manual call points

- Fire alarm systems: alarms/sounders, and control panels

- Fire protection systems: active (sprinkler) and passive (such as fire walls and fire-rated doors)

- Smoke control systems (pressurisation and extract systems)

- Building egress systems (including exit signage).

Safety system components rely on connection to the power network. Fire resistant cables are often used to provide power, or to make connections between emergency equipment and control panels. When this is the case, they function as “active” elements since they must maintain electrical continuity or transmit a signal for an adequate amount of time.

Three main technologies are used to produce fire resistant cables.

First generation designs were based on copper conductors wrapped with mica tapes and cross-linked polyolefin. In this case, the core technology is the mica, and cable performance is related to its quality, nature, suppliers, and taping.

Second generation cables were based on conductors insulated with silicone rubber. This material has the property of forming a ceramic shield when burned. This maintains high electrical resistance and it is the most common solution for building applications.

For the latest generation of Fire-Resistant cables, we broadened our range with innovative cables based on the patented INFIT™ insulation technology which combines the advantages of both mica and silicone rubber insulation, but without their drawbacks (mica is difficult to strip, while silicone is soft and brittle). INFIT™ fire performances are similar to usual market technologies (silicone rubber or mica tape), but brings exceptional mechanical performance, making the installation easier and creating value with important time-saving and thus cost-saving advantages.

With INFIT™ cables, it is possible to connect all the devices of a fire detection system, including smoke detectors, to ensure that fires are detected and alarms raised. All of this ensures a rapid escape and contributes to effective firefighting.

We focus on your needs

At Nexans, our mission is to provide innovative products and solutions that meet the safety needs of our cable customers. We give our clients the power to design, install and manage their projects with the highest level of safety for your customers. Nexans Fire Safety solutions and services allow to Anticipate fire risks, Secure assets and Protect Life.

We back this up with comprehensive information and advice to help you make informed fire safety decisions – so we can electrify the future with confidence.

Author

Franck Gyppaz is the head of the Fire Safety Systems Design Lab at AmpaCity, the Nexans Innovation Hub. He has been working in the cable industry since more than 20 years, being involved in the domain of fire safety and developing innovative technologies, cable designs and a fire test lab with the ISO17025 accreditation and UL certification. He is also active in the field of standardization members of different groups at national and international levels. His position leads him to manage relationships with all the actors of the fire safety ecosystem to propose integrated systems to our customers.

Like other sectors, the automotive industry must evolve to meet future economic and ecological challenges. Currently, thermal vehicles are responsible for nearly 10% of CO2 emissions worldwide. In developed economy such like in France, this figure rises to 15%. The electrification of these vehicles is therefore a key issue in the transition to a low-carbon economy.

According to the World Energy Outlook 2022 published by the International Energy Agency, the increase in global electricity demand between now and 2030 is equivalent to adding the current electricity consumption of the United States and the European Union! Such an increase in electricity is in the range of +5,900 to +7,000 TWh depending on the scenario.

The main contributors to such an increase are:

- electrical transport in advanced economies,

- population growth and demand for cooling in emerging markets and developing economies.

Electric mobility is an important stake and a major driver of additional electricity demand. However, this objective should not only focus on the development and evolution of vehicles by manufacturers but also take into account the infrastructure. It is important to focus on the need for recharging infrastructure and innovative technologies dedicated to electric vehicles (EVs), which should enable users of this type of vehicle to travel anywhere, at any time, with complete peace of mind and ensure the functioning of the electrical system.

Electrical vehicles: a major change coming required by energy transition

The public authorities in several countries are multiplying initiatives to foster this evolution of mobility solutions. Among the actions in force or under study, a growing number of countries have pledged to phase out internal combustion engines or have ambitious vehicle electrification targets for the coming decades. In Europe, the objective set is to stop the sales of new combustion-powered vehicles by 2035.

The IEA Announced Pledges Scenario (APS), which is based on existing climate-focused policy pledges and announcements, presumes that EVs represent more than 30% of vehicles sold globally in 2030 across all modes (excluding two- and three-wheelers). While impressive, this is still well short of the 60% share needed by 2030 to align with a trajectory that would reach net zero CO2 emissions by 2050.

By 2025, it is estimated that the electric vehicle market in France will be worth 12 billion euros, including 8 to 11 billion euros in sales of electric vehicles, 150 to 250 million euros for charging stations and 300 to 600 million euros for the sale of electricity needed for charging.

The fast deployment of EVCS, key condition of the development of electric vehicles

This transition to electric vehicles requires three main conditions to reach the target ambition:

- The development of new & attractive vehicles, with the following issues at stake: battery capacity vs. the energy density of a litre of oil, the availability of mineral resources to fully renew the world’s car fleet (due to the scarcity of rare metals), the challenge of the environmental footprint of an electric vehicle (beyond the sole issue of metal scarcity).

- The availability of energy where and when the vehicles will be charged. While the impact of an EV on the electricity grid is very limited at the domestic level, the 22 million electric and hybrid vehicles expected in 2025 in Europe will significantly increase the overall demand for electricity (from 4,860 in 2020 to 47,000 GWh in 2025).That will require both grid reinforcement, more energy and moreover a smarter way to manage load to balance usage with energy availability.

- Finally the deployment of a dense network of charging stations (EVCS) to provide a solution to the consumer in mobility.

Basically the EVCS network will be efficient if it is deployed as a global ecosystem fitting with consumer needs in four main applications:

- Charging “at home” (90% of EV loads are today done at home, individual or collective);

- Charging “at work” (tertiary or institutional buildings, factories,..);

- Charging “in the city” (shops, restaurants, public parking,…);

- Charging “in journey” (highways).

Each of this application obeys to its own constraints regarding economical cost of deployment, expected time for loading, competition with other vehicles “in queue”, energy billing to the user… Whatever the type of charging solution to be offered (in AC for the majority of needs or DC for fast charging), it will impose significant constraints on the electrical network that needs to be anticipated.

This large and complex ecosystem to deploy in a decade will require major investments but also strong innovation for a maximized installation scalability and smart energy management.

Partnerships and innovation are key

To illustrate this challenge of innovation, we can highlight for instance 2 projects involving Nexans R&D teams in partnership with Enedis in the last years:

- “BIENVENU” project: How to propose scalable and economical Charging infrastructure in collective housing buildings designed far before Electrical Vehicle rising (only 2% equipped in 2022 in France, for ~45% of population living in collective housing) ?

- “SMAC” project: How to create technological conditions to allow Vehicule-to-Grid (V2G) to inject the energy stored in EV batteries in the grid during the peaks of energy consumption or to compensate intermittent energy production from renewable sources?

Nexans also propose with its partner e-Novates a complete range of AC charging stations from 7 to 22 kW designed to fit various indoor/outdoor applications for Business or Public customers.

This product range will be entirely renewed in 2023 with new models fast to install and compatible with the new standard ISO 15 118. In parallel will be introduced the new version of Nexans scalable cabling solution “NEOBUS”, designed in partnership with MICHAUD, dedicated to underground parking with specific fire safety risk integrated.

Nexans is therefore a key player in this evolution of the electric vehicle market. The new solutions proposed will greatly facilitate the daily life of users, both in the private sector and on public roads, and will improve the attractiveness of these new vehicles.

It is clear that the elements of differentiation are the key factors of innovation:

- for vehicles, overall design, autonomy linked to battery power and efficiency, and reliability over time are differentiating factors;

- for recharging infrastructure equipment, we believe that the main differentiation criteria are not linked to hardware but to the digital layer which allows monitoring of the charging stations, interfaced with payment methods, and applications which improve the customer experience. The second area of differentiation is the ease and speed of installation of the kiosks and their connection to the electrical network.

To limit the impact on the environment

The deployment of electric vehicles and their growing share in mobility will have a significant impact on reducing global warming, provided of course that decarbonised electricity is produced and used. However, it is also important to consider the impact of electric vehicles on resources, particularly copper. In 2020, production was 21 Mt for an almost equivalent consumption. Demand will accelerate due to electrification and particularly electric mobility.

In concrete terms, a traditional thermal vehicle requires 20kg of copper, a hybrid vehicle needs twice that amount, 40kg, and an electric vehicle requires 80kg of copper on average, i.e. 4 times more than a conventional vehicle (this amount can reach up to 200kg for certain models like Tesla).

20kg

of copper are required for a thermal vehicle

40kg

of copper are required for a hybrid vehicle

80kg

of copper are required for an electric vehicle

To this consequent increase in metal dedicated to electric vehicles, we can add the copper needed for the recharging infrastructure, the AC and DC recharging equipment, but also the connection system to the electrical network. A conservative estimate is that 3Mt of metal will be needed for this transition.

To limit the impact of the electricity transition on copper resources, it is necessary to accompany the change by a copper recycling chain and the establishment of a circular economy ecosystem.

Buckle up! Frédéric Lesur is about to take us on a test drive with Thibault Dupont. Electric vehicles and charging stations, their build, and the future challenges that lie down the road – it’s all in this episode of What’s Watt.

Authors

Cyrill Million is in charge of Electric Vehicle Charging Solutions department, part of Nexans Power Cable & Accessories BU.

Cyrill joined Nexans in 2021 as Marketing & Strategy manager with mission to amplify Nexans position on energy transition markets and to promote innovative solutions to Nexans key partners.

He holds a Master of Aeronautics Engineering from Supaero, France.

David Myotte is Marketing and Strategy Manager in the Power Distribution Cables & Accessories Business Unit of Nexans.

After 15 years in automotive industry and 7 years in steel industry, mainly in sales positions, he joined Nexans beginning of 2020, in charge of Nexans Accessories Sales in North and South Europe. In his current role, on top of elaborating marketing strategies and new offers aiming at enhancing Nexans customers’ experience and satisfaction, he is responsible of the sales of Nexans Electrical Vehicle Charging Stations (EVCS).

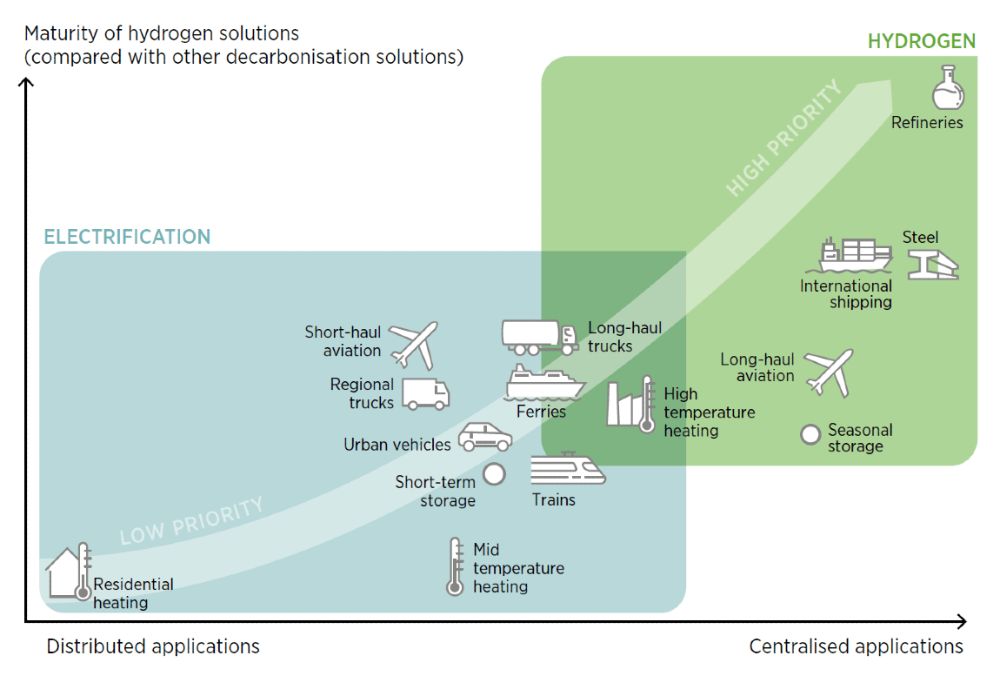

The race to net zero is on, and to cross the finish line by 2050 industry needs to shed the burden of fossil fuels. But which energy sources have the power to replace them?

Although electricity is the undisputed front-runner when it comes to cleaner energy alternatives, electrification falls short in parts of the world that are isolated or lack solid electrical infrastructure. And this is without mentioning all the “hard-to-abate” sectors such as steel industry or intensive mobilities.

That’s where hydrogen steps in. The gas is already used as a chemical reagent in industries such as oil refining and agrochemicals, to the extent of 90Mt a year. And now a boom is on the cards, with demand predicted to increase by a factor of 4 to 6 by 2050. Production from water electrolysis would then account for over a quarter of the global power demand!

Decarbonizing hydrogen

But just how virtuous is hydrogen? Its production processes vary wildly in their environmental impact, leading to the informal and sometimes bewildering hydrogen rainbow classification system. The vast majority of hydrogen today comes from fossil fuels via high temperature steam reforming of methane, with 10kg of CO2 emitted for every kilogram of H2. This type of production is responsible for 2-3% of global CO2 emissions, on a par with air-travel!

Making hydrogen is also possible using electrolysis. This process, that splits water molecules into oxygen and hydrogen, is energy-intensive – 50-60 kWh generates 1kg of hydrogen. But when the electrolyzers are connected to renewable energy sources, very low-carbon hydrogen can be achieved.

However, its low density at room temperature means it must be compressed at high pressures – up to 700 bar – or cooled to a very low temperature – -253°C (20K) – to turn it into a liquid that can be transported and stored.

Furthermore, the carbon intensity of hydrogen produced by water electrolysis depends on the energy mix of the electricity source. In some countries with lots of coal power plants, the carbon footprint of electrolysis process could be more detrimental than steam methane reforming.

High-pressure challenges

New applications for hydrogen are springing up in the fields of energy and mobility. But to ensure the boom doesn’t run out of gas, big changes must be made over the whole lifecycle.

This starts with production. For hydrogen to truly contribute to a net zero emission world, the energy used for the electrolysis must come from renewable sources such as onshore or offshore wind and solar farms which Nexans already connects. This will have a direct impact on hydrogen’s price tag, which will then be driven by the costs of electricity and capital investment in farms and electrolyzer units.

Once it has been produced, all this hydrogen still has to reach the end user, and the right storage and transportation solutions could mean the difference between success and failure. Just one kilogram of hydrogen takes up 12m³ at atmospheric pressure, and very high pressures (up to 700 bar) are needed to bring this volume down to manageable levels.

The solution? Liquefy hydrogen. This has been a practice in aerospace for decades, and new applications for liquefied hydrogen (LH2) are emerging, such as:

- Overseas transportation of energy between production and consumption places. The Hystra project – producing hydrogen in Australia and shipping it by cargo to Japan – was a world first, enabled by Nexans high-flexibility cryogenic transfer lines. Projects aiming at deploying the infrastructures for maritime transportation of LH2 are now starting in key maritime ports to prepare the forthcoming worldwide trade of LH2.

- Aeronautics. Airbus is aiming to fly the first commercial plane fueled with LH2 in 2035. This will mean a complete change of airport infrastructures to supply hydrogen, electricity and sustainable aviation fuels, in places where safety and floor space are major stakes.

Innovation at every stage of the game

Nexans is contributing new technology and business solutions all the way down the hydrogen value chain.

- On the production side, we provide solutions for optimizing the operating and capital expenses of producing renewable energy. Applied to electrolyzing units, our unique know-how on grid design could help achieving optimized hydrogen production facilities

- On the storage and distribution side, Nexans has long been a pioneer in supply infrastructures for cryogenic fluids. Our vacuum-insulated flexible transfer lines offer easy-to-install, safe and reliable solutions for tank-to-tank transfer of LH2. Their “plug-and-play” installation is as easy as laying a power cable and beats conventional rigid piping systems when it comes to speed of implementation. We recently equipped the world first loading systems for ship-to-shore transfer of LH2 in Kobe, Japan, with long length, high flexibility cryogenic transfer lines capable of high flow rates, numerous bending cycles and minimal boil-off.

The future is hybrid

If smartly combined, electrification and hydrogen will team up to contribute to more efficient low-carbon energy supplies. Pushing forward the complementarity between the two energy vectors, we are currently developing new concepts of hybrid lines able to vehiculate both hydrogen and electricity in the same system, including:

- Subsea umbilical systems to transfer hydrogen, data and electricity between offshore production units, such as wind farms or energy islands, and land;

- Superconducting systems combining LH2 transfer and superconductivity for hybrid energy highways that can transmit impressive amounts of power over long distances and help modernize power grids.

Ultimately the transition to net zero will require a shrewd combination of many interlocking energy sources and technologies. Together with electrification, Nexans is empowering hydrogen to become a safe, effective, economically and environmentally viable contributor to the energy supply of tomorrow.

Author

Anthony Combessis is manager of the Hydrogen Techno-platform, at Nexans Innovation Services and Growth. He is in charge of identifying and developing innovations and new market opportunities for Nexans in the hydrogen ecosystem, with a special focus on cryogenics solutions. Anthony joined Nexans in 2011 as R&D project manager working on electrical vs. physical-chemical properties of polymers, instrumentation and nanocomposites. He holds a Ph.D. in polymer nanocomposites from Grenoble University, France.

Plastic is not good for the environment: everyone knows it and everyone makes efforts to avoid it, or at least to sort it better. However, it is still essential in many sectors. Indeed, it remains very important in the design of cables because of its exceptional properties: mechanical, dielectrical, processability, durability…

The problem lies in the poorly managed and uncontrolled plastic waste streams that endanger ecosystems around the world:

- Over 460 million tons of plastics were produced in 2019,

- Up to 50% of plastic waste was sent to landfill,

- Despite current initiatives and efforts, the amount of plastics in the oceans has been estimated to be around 75-199 million tons. According to the Ellen MacArthur Foundation, by 2050 and without action, there will be as much plastic as fish in the sea (1kg for 1kg).

To face the growing volume of plastic produced, used and dumped, industries have to evolve to a fully circular model in which end-of-life plastic products are not discarded but transformed to create value. Innovation, regulation and international collaboration are needed to enable this transition.

In addition to resource management and pollution issues, plastic materials have an impact on greenhouse gases. A kg of polyethylene produced in Europe for plastic manufacturing has a carbon footprint of roughly 1.8 kg of CO2 equivalent.

Plastic material: versatile and unavoidable

Industrial-scale plastics production began in earnest in the 1940s and rapidly increased in the 1950s. More than 8 billion tons of plastics have been produced worldwide since 1950, making it a widely used manufactured material (Geyer et al., 2017).

Plastics offer various benefits such as a high strength-to-weight ratio, and the ability to tailor their physical properties to be hard or soft as needed. This versatility and durability, combined with the low cost of plastic production, is the major reason why plastics are currently used in almost every sector.

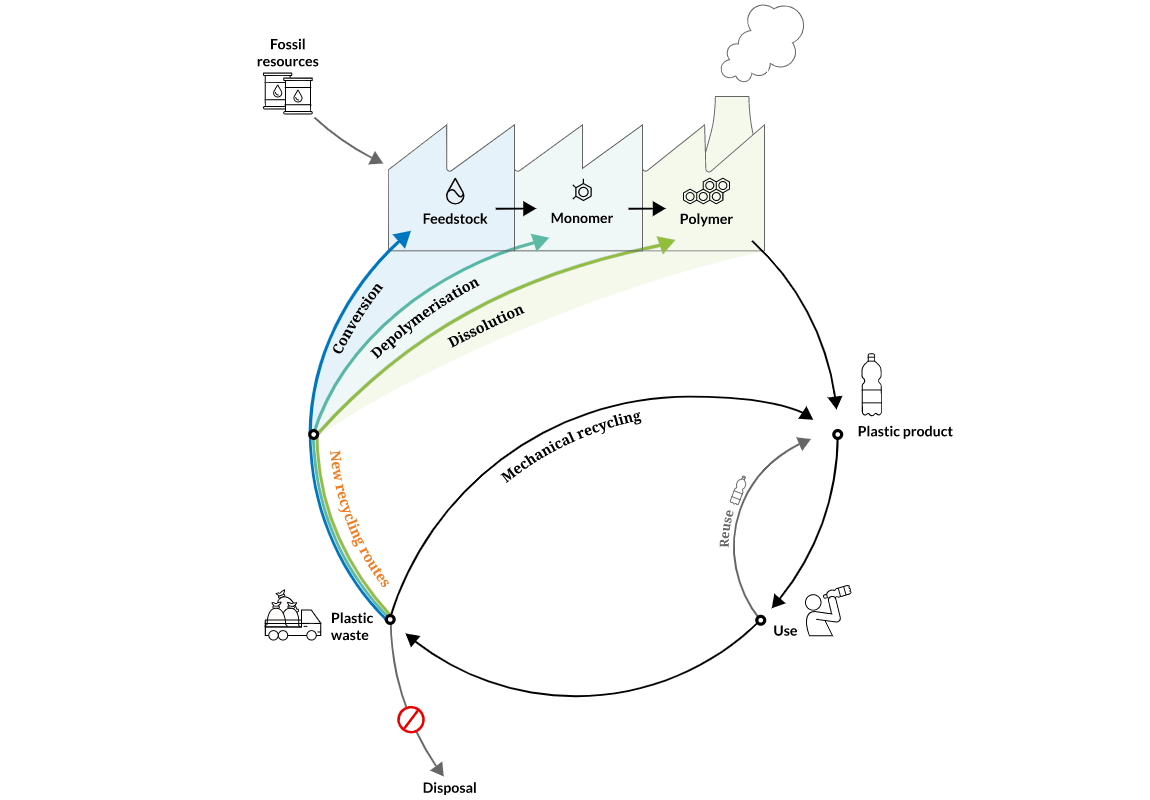

A necessary transition to circular plastic

Today, almost all plastic is derived from materials made from fossil energy (primarily oil and gas). This causes several problems:

- If dependence on plastics persists, it will represent 20% of annual global oil consumption by 2050,

- Greenhouse gas emissions for plastics will reach 1.34 gigatons per year by 2030 if it remains in its current form,

- The ability of the global community to keep temperature rise below +1.5°C or even +2°C by 2100 will be threatened.

According to OECD, “Plastic pollution is growing relentlessly as waste management and recycling fall short”. Indeed, it is estimated that only 9% of plastic waste is recycled, and 22% is mismanaged. Due to the durability and strength of the material, plastic waste remains in the environment and takes decades or even centuries to decompose naturally. It involves the loss of biodiversity and alteration of ecosystems (MacLeod et al., 2021).

Hopefully, a transition of plastic materials is possible:

- Recycling: although recycling is currently the simplest and most widely used solution to transform plastic waste into new products, efforts can be made in terms of sorting and separation. Among all the recycling routes, we differentiate: the simple reuse (direct wastes reuse within the manufacturing processes for example), the mechanical recycling (crushing/powderization after a sorting/separation for example) and the chemical one (with different routes: dissolution, depolymerization or conversion). These technologies make possible to approach the recycling of the wide family of plastics with different levels of complexity and quality.

- Eco-design: The principle of eco-design is about taking into account the entire life cycle of the product, from the materials used to its recovery and recycling and to take this into account at early stages, i.e. during the material conception. Meaning for example the use of recycled or biobased materials, increase the product lifetimes, select the materials to facilitate the recycling, decrease the weight of plastics used…

Nexans and circular plastics

The major challenge of industrial activity is to drastically limit the impact on the environment. There are three main issues that are interconnected:

- the impact on greenhouse gases and the climate,

- the impact on resources, particularly copper and aluminum as well as plastic materials,

- the impact on biodiversity, which requires the substitution of certain additives (e.g. REACH substances) and the control of the entire life cycle in order to limit and eliminate pollution.

Environmental challenges are at the center of Nexans cable solutions development. We commit to reduce the environmental footprint of our cables thanks to the selection of materials. More than ever, Nexans aims to invent innovative materials that combine eco-design, performance, durability and recyclability.

Extend the use of recycled materials

The incorporation of recycled materials in new products is a challenge for all industries. Nexans has launched a company-wide initiative to use up to 30-60 % recycled plastics in different cable families across the electrification chain.

Recover our wastes

Nexans works to improve the recycling of end-of-life cables and offers to collect customers’ wastes through Nexans Recycling Services. Moreover, Nexans has an objective to recycle 100% of its production wastes by 2030, with a circular economy dynamic. Plastic wastes sorting and valorization are now at the center of several R&D projects to answer all the blocking points (e.g. legacy additives, plastic mix separation, crosslinked polymers recycling…).

Eco-design of our cables

The current valorization efforts of existing end-of-life cables highlight substantive problems linked to their complex designs or to their various components. New products are now created with a strong will of eco-design including:

- Limit and replace the use of hazardous substances,

- Development of plastic materials that are more easily recycled,

- Simplification of cable designs,

- Improvement of the cable lifetimes.

Innovation will be key to the transition from a linear to a circular model for plastics materials. It requires the development of specific technologies, but will also have to include supply chain and business model components that will be only possible through ecosystems.

Author

Jean-François Larché is Team Leader Advanced Materials working for Innovation, Services and Growth in Ampacity, Nexans’ innovation hub in Lyon. He is working on material development transversally for the Group with a focus on product sustainability (recycled content, recyclability…). He joined Nexans in 2011 working for 8 years mainly on cable durability.

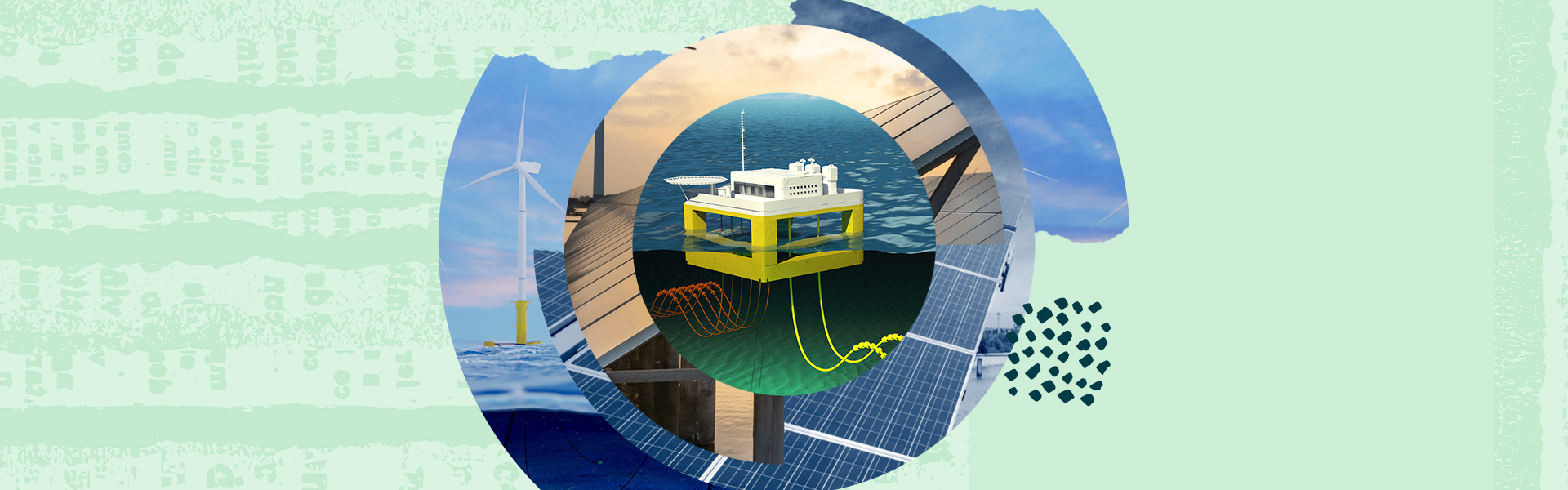

Floating technology is a hot trend in the world of renewables. We examine the drivers and discover how Nexans is helping to turn the dream of floating offshore wind – and solar – into a reality.

Offshore wind generation has seen tremendous growth over the past decade. Global offshore capacity has now reached 35 GW – an almost nine-fold increase since 2011. An additional 235 GW of offshore capacity is expected by 2030, taking the global total to 270 GW.

Winds of change

Turbine technology has made huge strides since the first wind farms appeared in our oceans more than twenty years ago. Today’s turbines are bigger and more efficient than ever, with rotor diameters in excess of 200 metres and power ratings of 10 MW and more. These advances have played a critical part in driving down the cost of offshore wind.

Almost every offshore wind turbine in existence today depends on bottom-fixed foundations, which are a good solution in relatively shallow waters – those up to 60 metres deep. These foundations are steel and concrete footings that attach the turbine structure directly to the seabed.

The vast majority of oceans and seas have waters that exceed 60 metres in depth – and this is where the highest and most consistent winds are found. In Europe, for example, 80% of the wind resource occurs over waters with a depth of 60 metres or more. Conventional foundations are not cost effective in these situations. So there are large areas where wind resources are untapped.

New horizons for offshore wind

Floating wind turbines overcome the problem of providing foundations in deep water. Instead of being rooted to the seabed, turbines are mounted on a floating substructure that is tethered with mooring lines and anchors.

All of this is a game changer for offshore wind. Rather than being restricted to a depth of 60 metres, floating turbines can be deployed in waters up to 1000 metres deep – and potentially much more.

This has exciting potential to expand the geographical reach of offshore wind. The northern part of the North Sea basin is one example. The depth of waters here typically far exceeds 60 metres, putting them beyond the reach of conventional foundations.

Hywind Scotland in the UK – the world’s first floating wind farm – highlights what can be achieved. Sited about 30 km offshore in waters up to 120 metres deep, Hywind has been in service successfully since 2017. Hywind has the highest capacity factor for any wind farm in the UK: in 2020, it set a new UK record, achieving an average capacity factor of 57.1%. This compares to an offshore wind average in the UK of about 40%.

The technology behind floating wind is set to have an impact far beyond the North Sea, particularly in geographies where the sea gets very deep, very near the shore. Examples include the Mediterranean basin, the west coast of the United States, South Korea and Japan – all of which have huge offshore wind resources waiting to be tapped. Floating wind can also be deployed in shallow waters where seabed conditions prevent the use of conventional foundations.

Making floating wind a reality

Currently, floating wind accounts for just 0.1% of the offshore wind total. But that is set to change. Forecasts by the Global Wind Energy Council suggest that by 2030, floating wind could account for 6.1% of all new installations with an estimated 16.5 GW of new capacity added within the next ten years. Robust, cost-effective technologies hold the key to achieving this.

One of the big technical challenges with floating offshore wind is exporting the electricity they generate. There are three factors in play. First, cable links between wind farms and the shore are longer because turbines are typically sited further out to sea. Second, the power levels that must be handled are increasing as turbines grow in size. Third – and most importantly – dynamic cables are required. These must be capable of accommodating movements of the floater structure caused by currents, tides and wind. Resilience is critical.

Smarter dynamic cables

Nexans’ track record in high-voltage submarine cable systems and dynamic cables means the company is ideally placed to support the development of floating wind. Indeed, Nexans supplied dynamic cables for the Hywind Demo and Hywind Scotland floating wind projects. The company’s experience has deep roots: Nexans developed its first dynamic cable back in 1983.

Today, the innovation continues. The focus is now on developing HV dynamic cables that can handle more power and greater voltages than ever before. This new generation of cables will be lighter and more flexible than traditional subsea cables. They will also be smarter, thanks to the integration of optical fibre elements to provide real-time monitoring – providing critical information on various parameters of the cables and ensuring years of reliable operation.

Floating Wind Turbines: The skyscrapers of the sea

In this episode of What’s Watt, Frédéric Lesur and Maxime Toulotte present the ins and outs of floating wind turbines. How they are installed, how they generate energy, and how much energy they can produce from ocean winds. Get ready to face strong gusts, as you might be amazed by what you’ll see.

Floating offshore solar

Utility-scale floating solar power is one of the fastest-growing renewable technologies. Photovoltaic arrays are mounted on rafts anchored out in open water, with subsea cables to channel the power back to the land.

The most challenging aspect of the project from a cabling point of view is handling dynamic loading, caused by movement of the platform in response to wind, waves and tides. Nexans is utilising a three-core cable design of a type well-proven in offshore wind farm and fish farming installations. The 5 km cable is being manufactured at our Rognan plant in Norway.

The beauty of floating solar is that it dramatically expands the potential area available for siting solar arrays – without the need to acquire land. Growth in the floating solar sector is strong. Almost 10 GW of new floating capacity is expected to be deployed by 2025.

Author

Maxime Toulotte is the Head of Technical Marketing of Subsea and Land systems Business Group in Nexans, where he has the responsibility to develop and maintain relations with technical and engineering departments of clients and partners for subsea high voltage cables.

Maxime has held several positions as Sales & Tender Manager and Lead Engineer for high voltage submarine cable system projects.

Maxime holds a Master’s degree in Electrical Engineering from the Grenoble Institute of Technology, France.

After more than a century in the shadows, Direct Current (DC) power could be set for a comeback.

The closing years of the nineteenth century saw a fierce battle to establish the best method for supplying electricity to consumers, with DC on one side (promoted by Thomas Edison) and AC on the other (backed by Nikola Tesla). DC lost, and the world has been dominated by AC ever since.

The story might have ended there but for two things. First, DC is remarkably efficient for long-distance bulk power transfer – indeed, it has been used in this role for decades. Second, more and more of the electrical devices we use are natively DC – everything from your mobile phone to LED lights and electric cars.

All of this is leading to a reappraisal of DC for transmission, distribution and even final consumption by electricity users. So how might this work in practice?

DC transmission

Transmission is the bulk transfer of electrical energy, typically over long distances. This is achieved using overhead transmission lines or underground (or subsea) cables. Using high-voltage DC (HVDC) for transmission instead of high-voltage AC has a number of advantages.

First, less material is needed. This is because DC requires only two conductors (AC needs three). Second, electrical losses are lower with DC because only active power is transferred (by contrast, AC transfers both active and reactive power). Third, the possible length of transmission links is much greater with DC thanks to the absence of reactive power.

HVDC is a proven technology – and it is getting better all the time. Recent developments include voltage source converters (VSCs) and improved transmission capacity for cables. This is achieved with higher voltages, higher operating temperatures, bigger conductor cross sections and the introduction of extruded technology. All of this means that the footprint and cost of HVDC projects is falling relative to the energy transferred. In short, HVDC transmission is becoming much more competitive.

A bright future for HVDC

Two important market trends are driving increased interest in HVDC transmission. The first is the growing demand for electricity interconnectors. These span oceans and link the grids of nations and regions. The second driver is subsea export cables for the growing number of offshore wind farms.

To date, some 15,000 km of HVDC submarine cables have been installed, using both MI (mass impregnated) and XLPE (extruded) cable technology. An additional 20,000 km of HVDC interconnectors are expected to be deployed by the beginning of 2030, not including offshore wind farm export cables. The installed base of extruded cables is expected to increase and equal the length of mass-impregnated cables by the end of this decade. Manufacturers of HVDC submarine cables are positioning themselves to capture the market by investing in more production and installation capacity.

Could DC be used for distribution as well?

Medium voltage (MV) and low voltage (LV) distribution networks, and power distribution within buildings, have long been dominated by AC. But a progressive shift to DC – achieved through the development of LV and MV microgrids – could bring energy savings, improved interoperability, easier renewable energy integration and greater sustainability.

Interest in DC microgrids is being driven by fundamental changes in the way that electricity is generated, stored and consumed.

First, power generation is becoming less and less centralised and moving closer to sources of demand. Rooftop solar photovoltaics and small wind turbines are examples. Solar photovoltaics are natively DC, as are some micro wind turbines.

Second, battery storage is becoming widespread. Uninterruptible power supplies (UPSs) are one example. These are used by businesses, such as data centres, to maintain supply security. There are also growing deployments of battery energy storage systems (BESSs) for grid balancing. On top of this, home energy storage systems are now becoming available. Last but not least, electric vehicle batteries have grid integration potential. A key point about battery storage is that most of it is distributed rather than centralised, and all of it is natively DC.

Third, on the consumption side, DC devices are now widespread and uptake is accelerating. As noted earlier, many commonly-used devices, from phones to LED lighting and electric vehicles, are natively DC. Today, all of these devices depend on adaptors to convert AC to DC.

All of this is creating an environment that is ripe for DC microgrids with generation and consumption in the same grid, backed up with battery storage – including electric vehicle batteries. One of the beauties of the DC microgrid model is that it removes the need to convert AC to DC, eliminating the need for adaptors – an energy saving in its own right.

AC/DC, Currents… and Rock N’ Roll Covers

In this What’s Watt video, Frédéric Lesur explains the difference between alternating and direct current, all while presenting some rocking’ performances to electrify your viewing experience.

How is Nexans enabling DC?

Nexans is a leader in the submarine HVDC market and the company continues to invest in growing its manufacturing and deployment capacity. In 2021, we launched Nexans Aurora, the world’s most advanced cable laying vessel. Nexans is well positioned to support the future needs of both transmission system operators and wind farm developers.

With DC deployments growing in the high-voltage transmission sector, the next step could be medium and low-voltage DC microgrids. These will need to utilise optimised cables, accessories and connectors to be technically viable. They will also need to be reliable and to meet the requirements for energy efficiency, sustainability and safety.

Authors

Hans Kvarme is the manager of Techno Platform HVDC XLPE, managing all R&D activities linked to HVDC XLPE for Subsea and Land Systems Business Group in Nexans. This involves research and development, but also qualifications of new and existing extrusion lines, materials, processes and accessories.

Hans has previously in Nexans held positions as Director of Engineering & New Product Development within Innovation, Service and Growth and Department Manager Tender Engineering in SLS.

Educational background is a Master’s degree in Electrical and Environmental Engineering from NTNU in Norway.

Samuel Griot is the head of electrical engineering department within Nexans Innovation.

He leads a team of experts developing new innovative solutions for low, medium and high voltage applications in order to answer the future needs for the electrical grids. Samuel joined Nexans in 2021 and has a strong background in electrical grid architecture and switchgears.

He holds a Master degree in electrical engineering from INSA of Lyon, France.