Nexans agit pour le climat

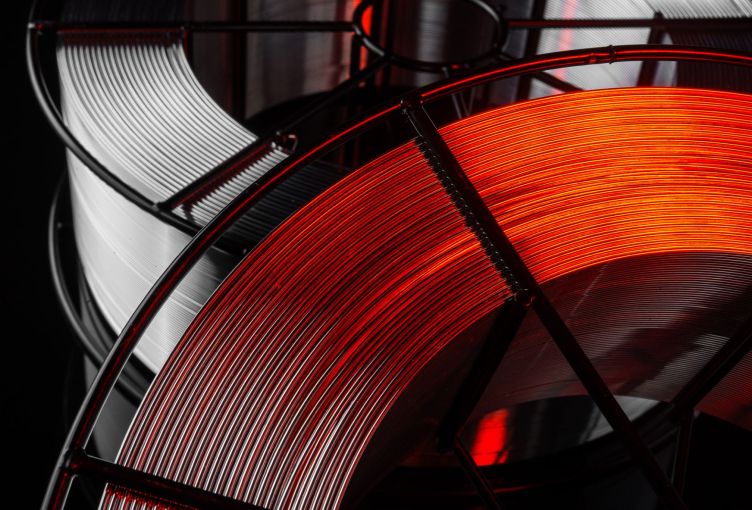

La réduction de notre impact environnemental fait partie de nos priorités. Pour réduire l’empreinte carbone de l’industrie du câble sur tout son cycle de vie, Nexans propose à ses clients des produits et services innovants, connectés et bas carbone, qui contribuent à agir contre le réchauffement climatique :

- Un nouveau matériau à base d’aluminium recyclé qui permet de réduire l’empreinte carbone des câbles électriques.

- Une offre bas carbone de câbles de réseau de distribution qui réduit les émissions de gaz à effet de serre de 35% à 50%, selon les produits.

- Un programme de sécurité des produits chimiques avec un objectif annuel d’élimination des substances dangereuses.