Interconnexions sous-marines : unir pour favoriser la transition énergétique

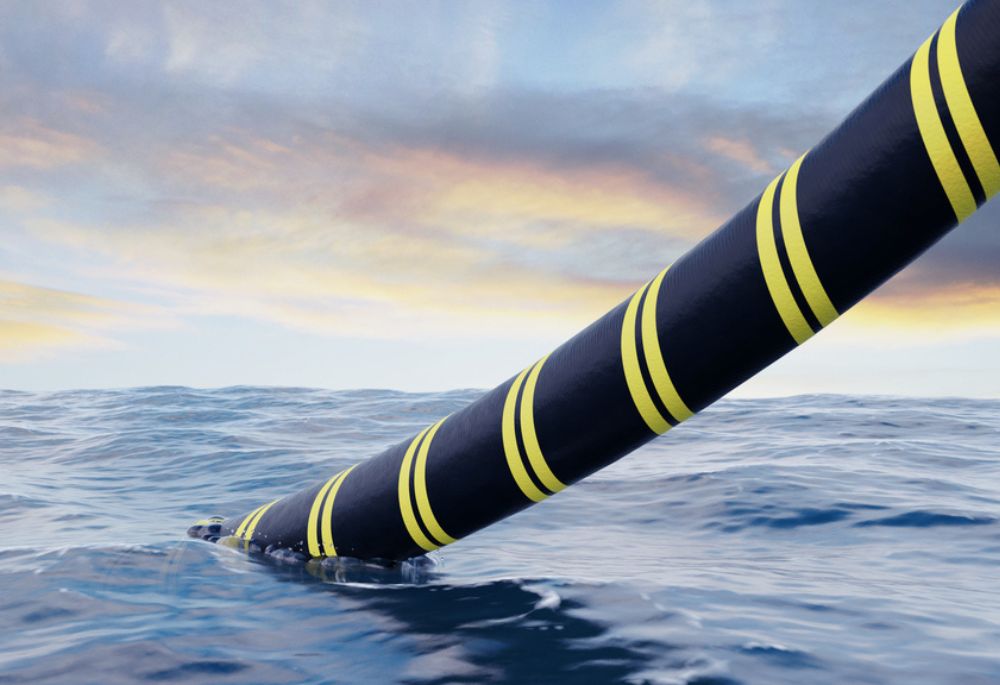

L’ère du tout électrique se profile et va nécessiter de transmettre davantage d’électricité renouvelable à travers le monde et d’assurer la fiabilité des réseaux électriques. Face à cette nouvelle réalité, déployer rapidement des interconnexions plus longues et plus efficaces pour relier les îles, les pays et les continents devient prioritaire. C’est pourquoi, chez Nexans, nous mettons nos 120 ans de savoir-faire et d’expertise dans la fabrication, l’installation et la gestion de projets de câbles sous-marins au service de l’électrification du monde de demain.

Défis liés aux interconnexions sous-marines

L’ajout de capacité mondiale d’énergies renouvelables est une des étapes à franchir pour construire un futur tout électrique et décarboné. Pour y arriver, nous devons opter pour des solutions durables et sûres, notamment en matière d’interconnexions sous-marines.

Gérer l’électricité supplémentaire provenant de sources renouvelables implique de déployer un nombre conséquent de nouvelles interconnexions avancées, stables et fiables. Ces câbles relient les régions et pays entre eux, et doivent être capables de transporter plus d’énergie sur de plus longues distances, notamment d’établir des liaisons sous-marines, pour favoriser le transfert d’électricité renouvelable entre les communautés.

Plus spécifiquement, les interconnexions à courant continu haute tension (CCHT) jouent un rôle stratégique dans la connexion des réseaux transnationaux, notamment car elles permettent de :

- augmenter la connectivité entre les réseaux électriques nationaux et de répartir l’électricité entre pays et régions en utilisant, par exemple, le surplus d’un pays pour combler le déficit en électricité d’un autre pays.

- stabiliser l’approvisionnement en électricité.

- mieux intégrer les différentes sources d’énergies renouvelables.

- gérer la temporalité des énergies renouvelables.

- renforcer la sécurité énergétique.

- réduire les pannes.

- réguler les prix.

Face à l’impératif de déployer plus largement les interconnexions entre les pays, plusieurs défis se posent. L’installation de câbles sur de longues distances nécessite de l’expertise, des technologies et des équipements spécifiques, notamment des navires câbliers pour assurer la fiabilité, la sécurité et la stabilité du réseau. Peu d’acteurs de l’industrie du câble peuvent remplir tous ces critères.

Chez Nexans, notre premier projet d’interconnexion, la liaison sous-marine Skagerrak entre le Danemark et la Norvège, a presque 50 ans. Depuis, les projets à travers le monde se sont multipliés et nous ont permis de parfaire nos connaissances dans les systèmes de câbles sous-marins à haute tension (HT) et de développer un savoir-faire unique. Nous intervenons sur une diversité de chantiers où nous créons notamment des corridors électriques entre pays pour renforcer leur sécurité et leur indépendance énergétique, mais aussi démocratiser l’accès aux énergies renouvelables et équilibrer l’offre et la demande internationale.

40 %

correspondent à la hausse

des besoins en électricité

dans les 2 prochaines décennies

13 500 tonnes

correspondent à la capacité combinée

des trois tables tournantes

installées sur le nouveau câblier

de Nexans, qui permettra d’installer

jusqu’à 4 câbles simultanément

443

projets d’interconnexions

menés par Nexans,

soit 46 GW installés,

+10 680 km de câbles

sous-marins déployés

Solutions Nexans

- Développer des interconnexions fiables pouvant transporter plus d’énergie sur de plus longues distances en mer et sur terre et favoriser ainsi l’échange d’énergie entre les communautés ou les pays.

- Déployer des solutions clé en main d’interconnexions CCHT pour connecter les réseaux transnationaux.

- Réaliser des opérations complexes d’installation de câbles dans toutes les profondeurs d’eau, des plus superficielles aux plus profondes, afin de relier les pays ou les parcs éoliens offshore.

Protection des câbles sous-marins avec Nexans IMR

Les principales lignes de transfert d’électricité sous-marins peuvent subir des pannes d’un an sans plan de contingence, entraînant des pertes économiques et des retards dans la recherche d’experts pour les réparations. Nexans offre son expertise, son personnel dévoué et ses ressources pour relever ces défis imprévus.

Avec les contrats d’Inspection, de Maintenance et de Réparation (IMR) de Nexans, les risques de défaillance des câbles sont minimisés grâce à des inspections et à une maintenance proactive, ce qui réduit les délais de réponse aux incidents. Nexans possède une solide expérience dans les réparations de câbles à l’échelle mondiale, y compris en Asie, en Afrique, en Europe et dans la région de la mer du Nord, avec plus de 40 ans d’expérience et l’installation réussie de plus de 50 joints de réparation en mer dans des conditions météorologiques difficiles.

Les câbles sous-marins de haute capacité sont appelés à jouer un rôle croissant dans la transition énergétique. Non seulement ces solutions haute tension économiques relient les capacités éoliennes offshore aux consommateurs à terre, mais elles assurent l’interconnexion entre les pays, améliorent la compétitivité des énergies renouvelables, facilitent les marchés et renforcent la sécurité énergétique.

, Nexans

Offrir des solutions clés en main pour les projets d’interconnexion qui incluent l’ingénierie, la fabrication, la pose, la protection et la mise en service des câbles sous-marins et terrestres HT.

Répondre aux exigences des opérateurs publics et privés avec un accompagnement sur mesure, des conseils, des solutions avancées.

Garantir la sécurité de l’approvisionnement électrique en fiabilisant les systèmes de câbles HT grâce à des solutions clés en main.

Nos capacités d’installation

Notre nouveau navire câblier

S’appuyant sur la technologie de pointe présente sur le navire amiral de Nexans, le Nexans Aurora, ce nouveau navire va plus loin avec un design amélioré, plus de confort et de capacités. Équipé de trois tourelles de câbles, offrant une capacité de chargement de 13 500 tonnes, et hébergeant une large gamme d’outils sous-marins, notamment des outils de jet et de labourage, ce navire sera capable de poser jusqu’à quatre câbles simultanément pour répondre aux exigences spécifiques des clients, notamment sur les projets de grande envergure. Ce navire sera livré en 2026.

CLV Nexans Aurora

Le navire câblier Nexans Aurora fait partie de l’initiative de Nexans visant à renforcer ses capacités de fabrication et d’installation pour répondre à la demande croissante de systèmes de câblage haute tension (HT), notamment pour les interconnexions et les projets éoliens offshore dans le monde entier. Il a la capacité de fonctionner même dans les conditions météorologiques les plus sévères et dispose d’une tourelle d’une capacité de 10 000 tonnes. L’équipement de pose lui permet d’effectuer des opérations d’installation complexes de produits flexibles, notamment des câbles électriques et des ombilicaux, en eaux peu profondes et profondes.

C/S Nexans Skagerrak

La fierté actuelle de la flotte est le C/S Nexans Skagerrak, avec une tourelle d’une capacité de 7 000 tonnes, un système de positionnement dynamique de pointe, un ROV de surveillance des touchers de fond et un trancheur Capject. Au fil des ans, ce navire de pose de câbles a installé les liaisons de câbles les plus longues et les plus profondes dans le monde, notamment la liaison Monita entre le Monténégro et l’Italie et la liaison NordLink entre la Norvège et l’Allemagne. Le navire est également capable d’effectuer des réparations en eaux profondes et peu profondes des liaisons de câbles électriques installées et peut déployer le système de tranche Capjet de Nexans pour la protection. Il existe plusieurs exemples du C/S Nexans Skagerrak dans des actions de réparation telles que les réparations de dommages aux câbles sous-marins HVAC 400 kV à travers le détroit de Gibraltar et le câble HVDC 450 kV entre la Norvège et les Pays-Bas.